- 0086 13321818576 (Steven Lee)

- info@3c-floor.com

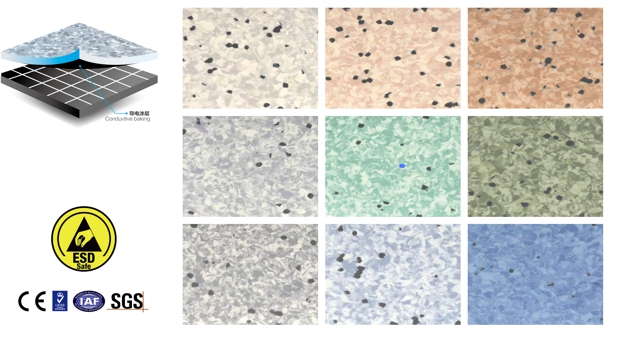

PVC anti-static floor

A new type of lightweight floor covering material that is very popular in the world today, also known as "light body material." Resilient anti-static floor China manufacturer & Supplier is made of PVC resin as the main body, which is made by special processing technology. The PVC particle interface forms a static electricity network and has permanent anti-static function. It looks like marble and has a good decorative effect. Applicable to telecommunications, electronics industry program-controlled computer room, computer room, clean factory and other areas requiring purification and anti-static.

1. Technical Indicators(Resilient Anti-Static vinyl Flooring Tile China manufacturer & Supplier)

Electrostatic conductivity: SJ/T11236-2001 <1.0×106

Static dissipative property :SJ/T11236-2001 1.0×106-1.0×109

Heating length change rate: GB4085-83 ≤0.4%

Water absorption length change rate: GB4085-83 ≤0.4%

Wear amount: GB4085-83 ≤0.02g/cm2 (1000 rpm)

Combustion performance: GB4609-84 FV-O <10s

Starting voltage: SJ/T10694-1996 <100v

Corrosion resistant, weak acid, weak base

2. Main Function(ESD viny Tile flooring China manufacturer & Supplier ):

(a) The conductive material is a stable carbon black, and the conductive network passes from the upper surface to the lower surface. This structure determines the permanent antistatic property;

(b) The substrate is a semi-rigid PVC plastic with abrasion, corrosion, ignition and flame retardant properties;

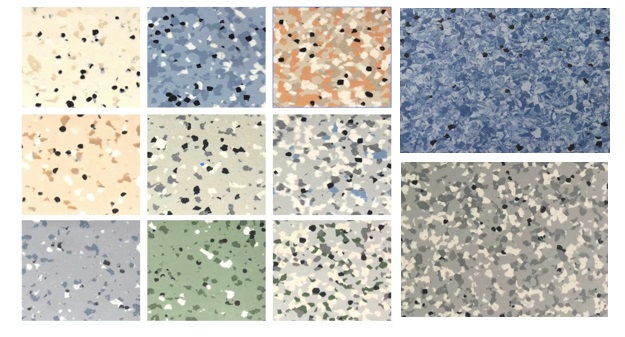

(C) It has a marbled outer surface, adjustable color, good decorative effect and convenient construction.

3. Environmental Requirements(ESD - Static Control Flooring China manufacturer & supplier):

Humidity requirement:

Temperature and humidity requirements are divided into three levels:

|

Level |

Temperature |

Relative humidity |

|

A |

21℃-25℃ |

40%-65% |

|

B |

18℃-28℃ |

40%-65% |

|

C |

10℃-35℃ |

40%-65% |

Electrostatic voltage

The absolute value of the electrostatic voltage should be less than 200V.

|

Level |

Dust particles with a diameter> 0.5 microns /L |

Dust particles with a diameter> 5 microns /L |

|

A |

≤350 |

≤3 |

|

B |

≤3500 |

≤30 |

|

C |

≤18000 |

≤300 |

4. Floor Classification(ESD Floors China manufacturer & Supplier):

By structure:

There are mainly three types of multi-layer composite and homogenous transmembrane and semi-homogeneous. The so-called multi-layer composite PVC floor is that it has a multi-layer structure, generally formed by stacking 4~5 layers, generally with wear-resistant layer (including UV treatment), printed film layer, glass fiber layer, and elasticity. Foam layer, base layer, and the like. The so-called homogenous transparent PVC floor is that it is homogeneous and transparent, that is, from the surface to the bottom, from top to bottom, are the same color.

By form:

It is a kind of coiled floor and sheet flooring; the so-called coiled floor is a soft and soft roll of floor, generally 1.5 meters, 1.83 meters, 2 meters, 3 meters, 4 meters, 5 meters, etc. Each roll has a length of 7.5 meters, 15 meters, 20 meters, 25 meters, etc., and the total thickness is 1.6mm-3.2mm.

By specification:

Sheet flooring has many specifications, mainly divided into strips and squares.

◆The specifications of strips mainly include

4" x 36" (101.6 mm x 914.4 mm) 6" x 36" (152.4 mm x 914.4 mm) 8" x 36" (203.2 mm x 914.4 mm), thickness: 1.2 mm - 3.0 mm.

◆The specifications of square materials are mainly

12"×12" (304.8mm×304.8mm) 18"×18" (457.2mm×457.2mm) 24"×24" (609.6mm×609.6mm)

Thickness: 1.2mm-3.0mm.

Wear resistance:

It is available in both general-purpose and durable versions. The main domestic production and use are general-purpose PVC flooring. Some places with very high traffic flow, such as airports and railway stations, need to be laid with durable PVC flooring, which has stronger wear resistance, longer service life and higher price.

5. Construction Process(Anti Static Flooring China manufacturer & Supplier):

material ingredient

Pvc resin, plasticizer, stabilizer, filler, conductive material and color mixing material are scientifically matched and polymerized by thermoplastic molding.

Characteristics

a, beautiful appearance, can provide a variety of colors for users to choose;

b, flexible, good foot feeling;

c, wear-resistant, low dust generation, durable and flame retardant;

6. Construction Quality(ESD Conductive flooring China manufacturer & supplier):

A. The ground resistance of the floor surface should be 105-108Ω.

B, no bubbles on the surface, no shelling phenomenon.

C. After the construction is completed, weld the gap and clean it.

7. Maintenance(Conductive vinyl flooring Rolls China mnaufacturer & supplier):

A. When placing objects on the floor, avoid heavy objects on the floor, and the contact surface should not be too small. If necessary, use wooden blocks.

B. When walking on the floor, you should not wear shoes with metal nails, and you should not use sharp objects or hard objects to scratch and tap on the floor surface.

C. Always use a damp, wet mop to mop the floor. Use a solvent such as alcohol for cleaning in a dirty place.