- 0086 13321818576 (Steven Lee)

- info@3c-floor.com

Our research and development team can combine a wide variety of fibers (nylon, polyester, Kevlar, etc.) and formulate the specific polymer chemistry for your customized product to improve efficiency and performance.

TECHNICAL SPECIFICATIONS:

Luxury Vinyl Planks

Plasticizer: DOTP

Phthalates: CPSIA Section 108 Pass

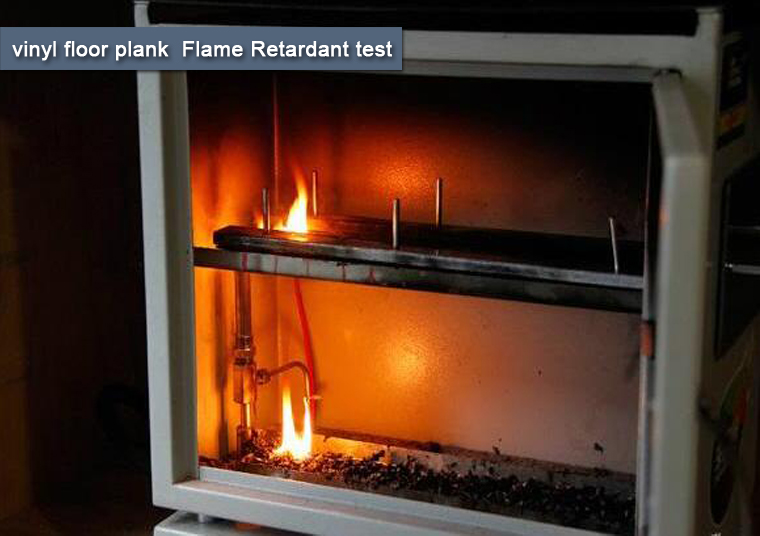

Fire Retardant: Class B1

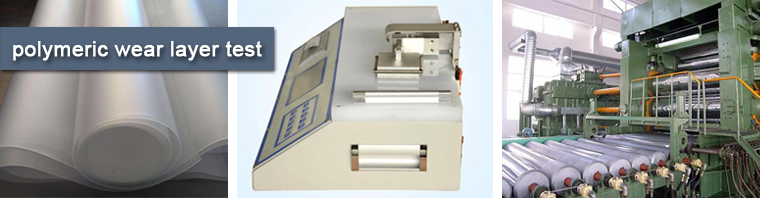

Wear Layer: 0.2mm(8mil)/0.3mm(12mil)/0.5mm(20mil) with Urethane Coating

3C Industrial WPC flooring

Wear Layer: 0.2mm(8mil)/0.3mm(12mil)/0.5mm(20mil) with Urethane Coating

Fire Retardant: Class B1

Dimensions: 1195(L)*141/163/192(W)

1220(L)*150/180/228(W)

1530(L)*180/228(W)

LUXURY CLICK VINYL FLOORING INSTALLATION INSTRUCTIONS

3C luxury click vinyl flooring is constructed with the patented products design. luxury click vinyl flooring can be installed in the existing flooring as the wood flooring, linoleum flooring and vinyl tile flooring.But our products can not be installed in carpeting surface.We will constantly look for advanced technology to make our products have higher quality and a variety of colours.If you have more questions please contact our customer service.

OWNER/INSTALLER RESPONSIBILITY

Inspect the color and quality of flooring before the installation.Our products are through the strict inspection and we all according to the international standards produce flooring.If you find the flooring having unacceptable quality problems ,contact the dealer at once. Owner or installer has the responsibility for flooring quality and colors to confirm whether it is consistent. It is important to examin flooring.

Job Site Conditions

1.Vinyl flooring installation should be done after all preparatory work has been completed.

2.DAJULONG luxury vinyl click flooring should be installed in a constant temperature environment between 59℉~85℉.Un-opened product cartons must be placed at this temperature at least 48hours before installing.

Storage

1. Flooring should be stored in a dry, ventilative and darkness room.

2. Flooring is not suitable for the uncontrolled environment before and during the installation.

3. Don't stack too many cartons together. It is best not to stack more than 8 cartons.

4. Must avoid strong impact.

Tools Required

• Utility Knife

• Carpenter square

• Cutting board

• Tape measure

• Pencil/Chalk

Subfloor Recommended

1. luxury vinyl click flooring can be installed over many surfaces such as concrete, wood and linoleum surface floors.

2. The subfloors is required to be dry, smooth, clean and flat.

3. At the wall, pipe and door around should have about 10mm of expansion joints.

4. For more than 100 square meters long and more than 10 meters wide room should leave the expansion space.

5. Between the door and ground should leave a no less than 3mm gap.

6. The flooring must lay a layer of dampproof mat when it is installed in the subfloors which is invaded by moisture.

INSTALLATION STEPS

1. Ensure the room’s length and width to determine if the first row will need to be cut.

2. Cut off the unsupported tongue of the first row so that a clean, solid edge is toward the wall.

3. Start installation from the conner of the wall . Tongue side must start facing the wall and it is careful to leave 10mm expansion space. Install the planks from left side to right side.

4. Install the next plank in the first row by angling the short side tongue into the short side of the first plank. Shift the plank down towards the end seam and lightly lift the previous plank in order to engage the end joints together.

5. Use the same method to complete the installation of the first row.

6. Place the short end tongue of the next floor panel at an angle against the previously installed floor panel and fold gently down.

7. Using gentle force and at an angle, you gradually, from left to right, push the long side tongue into the locking groove of the previous row.

8. Complete the whole row in the same way.

Glue Down Installation

1. If the area has a right angle of the conner ,start the installation from the right angle of the conner.If not ,choosing the the minimum deviation of the acute angle start installing.

2. Start the installation of the the minimum deviation of the acute angle along perpendicular to the outer wall of the wall.Determine if the planks will need to be cut

3. Clean the subfloor before the installation to avoid dirty things behind the planks.

4. An area the size of two installed rows is a good starting area.During sticking aligns to the angle first ,then the edge and the whole field of galley compaction.

5. Finally cut the extra planks not of the whole flooring of the wall.If it is small,you can also fold the extra plank to stick on skirting line.

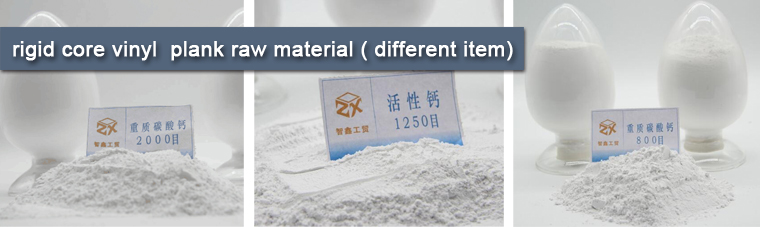

SPC vinyl plank floor based raw material is made from Calcium carbonate powder

Calcium carbonate is a two-component inorganic compound and is a main component of limestone (abbreviated as limestone). Its molecular formula is CaCO and its molecular weight is 100.09. Among them, calcium oxide (CaO) accounts for 56.03%, and carbon dioxide (C02) accounts for 43.97%. Calcium carbonate is widely found in nature. Now it has been continuously applied to the plastics processing industry. The calcium carbonate powder produced by the ultrafine calcium carbonate powder production line is used in the industry. Standards and specifications.

Classification of calcium carbonate

(1) Classification according to stone powder production process Calcium carbonate can be classified into light calcium carbonate, heavy calcium carbonate and activated calcium carbonate according to different calcium carbonate production methods.

1 light calcium carbonate. Also known as precipitated calcium carbonate, referred to as light calcium, is calcined raw materials such as limestone to produce lime (the main component is calcium oxide) and carbon dioxide, and then water to digest lime to form lime milk (the main component is calcium hydroxide), and then carbon dioxide carbonization The lime milk is precipitated by calcium carbonate, which is obtained by dehydration, drying and pulverization after comparison. Since the sedimentation volume of light calcium carbonate (2.4 to 2.8 ml of Mg) and the sedimentation volume of the specific gravity calcium carbonate (1.1 to 1.4 mL/g) are large, it is called light calcium carbonate.

2 heavy calcium carbonate. Referred to as heavy calcium, it is produced by mechanically pulverizing natural calcite, limestone, chalk, shells, etc. The sedimentation volume of the south of the heavy calcium carbonate is smaller than that of the light calcium carbonate, so it is called heavy calcium carbonate.

3 active calcium carbonate. Also known as modified calcium carbonate, surface treated calcium carbonate, colloidal calcium carbonate or Bai Yanhua, referred to as live calcium, is made by surface modification of surface modification of light calcium carbonate or heavy active calcium. The calcium carbonate modified by the surface modifier has a reinforcing effect, so-called "activity", so it is customary to refer to the modified calcium carbonate as active calcium carbonate.

According to the powder particle size classification, calcium carbonate products are two kinds of powders. According to the average particle size of calcium carbonate powder, calcium carbonate can be divided into granular calcium carbonate, fine powder calcium carbonate, fine calcium carbonate powder, ultrafine calcium carbonate. Powder and ultrafine calcium carbonate powder