- 0086 13321818576 (Steven Lee)

- info@3c-floor.com

Shanghai 3C Industry Co., Ltd has been focusing on PVC vinyl flooring manufacturing in China for over 20 years. Main products include SPC rigid core click flooring, WPC diamond core flooring, LVT click, LVT dry back, LVT Loose Lay, homogeneous & heterogeneous vinyl rolls.

Professional production team:

Over 1000 workers works in our 3 factories, production, testing, and production samples in each process of each production line, which promises every piece of our vinyl floor coverings 100% meet customer requirement.

Production Ability:

50 SPC production lines; 48 LVT production lines, 6 WPC production lines, 10 homogeneous & 6 heterogeneous; we have ability to produce more than 1.5million sqm floor coverings per month.

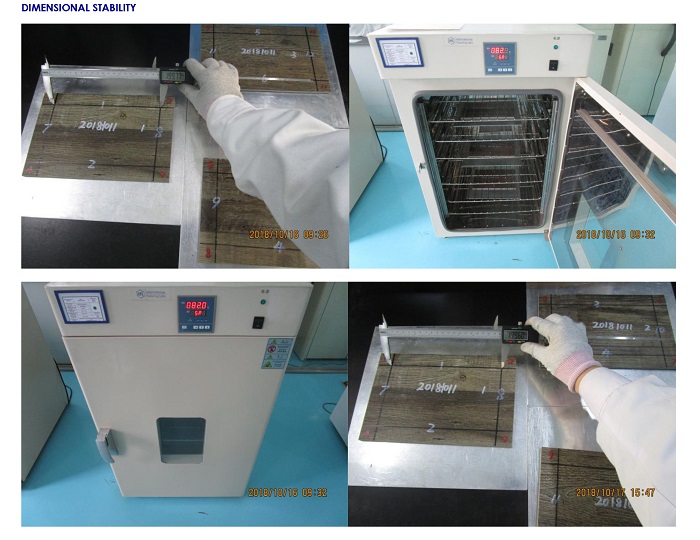

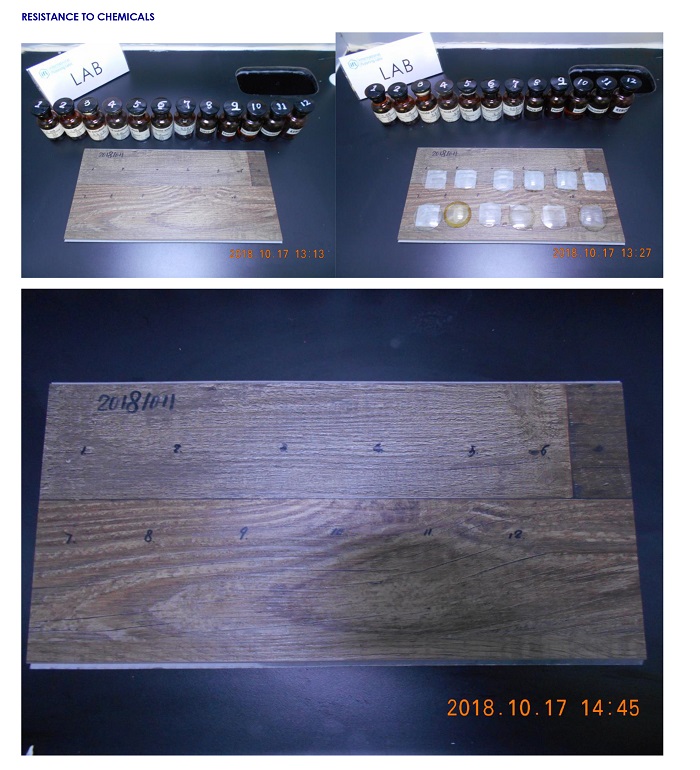

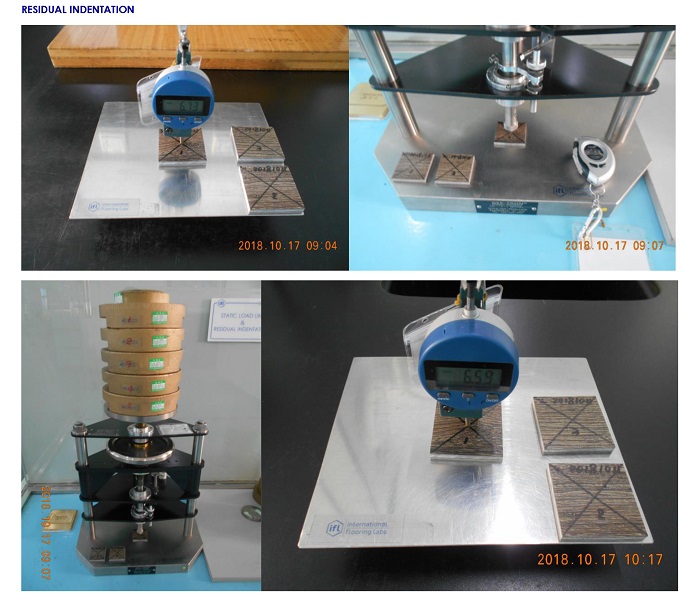

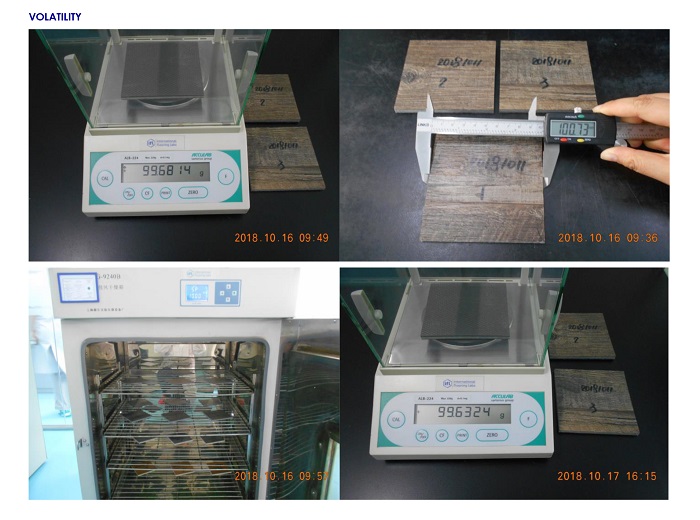

Quality Control:

Each production, we have test report by our own lab, test items include dimensions, wear resistance, anti-scratch, tearing and breaking strength, aging, 6P, Light degree etc..

Sales Team:

More than 20 international sales, 10 domestics, should be worked 3 months in workshops & other departments before sales, which makes sure every sales people knows each production process of the vinyl core flooring. Training every week to make sure every of our sales people knows latest international situation and the politics we could offer to customers.

After-sale Service:

Promise is promise; Feedback at first time; 24hours online service; any questions be answered within 24 hours.

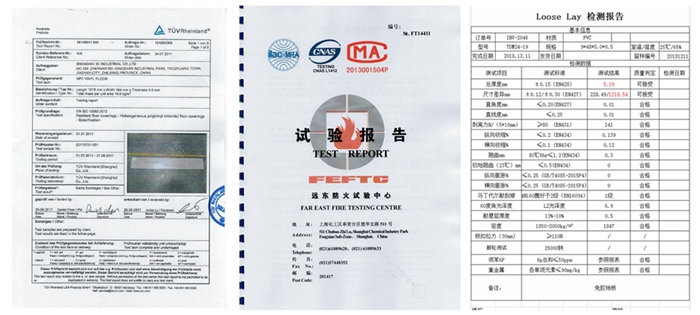

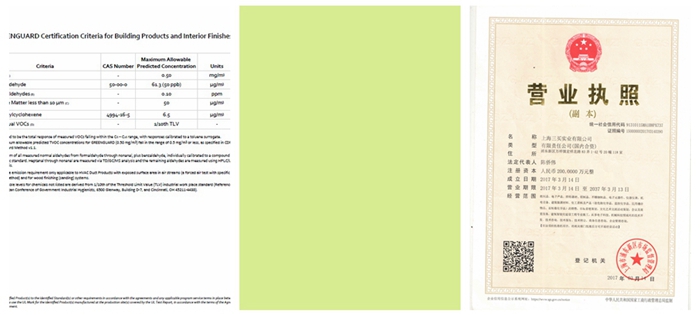

Product Certificates:

Company Certificates:

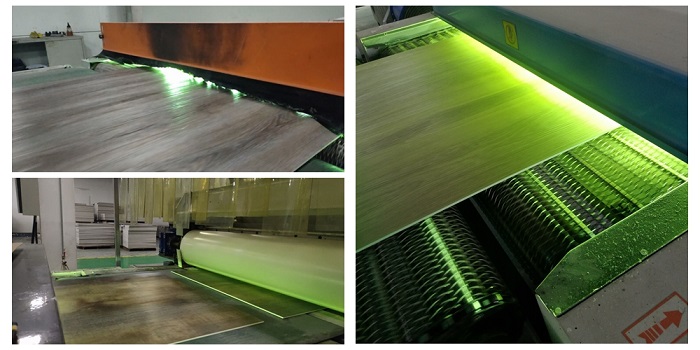

3C SPC Flooring production lines:

Wear Layer: Soft super clear PVC film

Production with washing component on the line, to make the wear layer clearer and with higher tearing and scratching strength, less separating out of the DINP.

Printing Film: 0.07mm digital printing white PVC film

Whiteness must be 95-degree, softness 40Pa, production speed must be settled properly, if faster than scheduled, the pattern not clear; if slower, the ink spread. Film reach 12P environment standard.

Color patterns selected and copied from raw wood and makes vinyl most similar to real wood

Rigid Core: PVC Resin, Calcium & plasticizer,extrusion

All raw materials 100% virgin, one-time extrusion 8mm thickness. Calcium should be 400 screen mesh, to make perfect feeling of the core. We also add little Carbon to make grey core for customers.

Backing liner:

IXPE: Polyethylene is the main raw material, and it is mixed with several other auxiliary materials that do not contain any harmful substances. It has excellent performance in durability, light resistance, and physical impact resistance. XPE itself is chemically stable, difficult to decompose, odorless, and elastic. Normal density 7.5X, 10X, 15X, 20X. Thickness 1mm, 1.5m, 2mm

EVA: (C2H4)x.(C4H6O2)y, Good softness, shock resistance, non-slip, strong pressure resistance. Thickness 1mm, 1.5m, 2mm

Cork: Normally 1.5mm and 2mm, made of wood composite.

Backing can be before and after cutting.

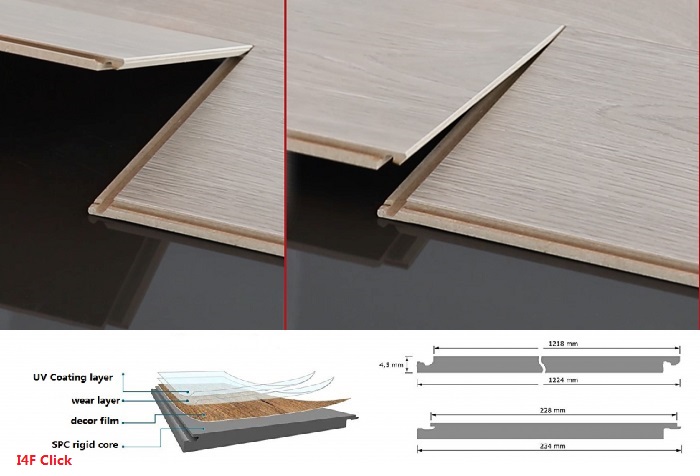

Click System:

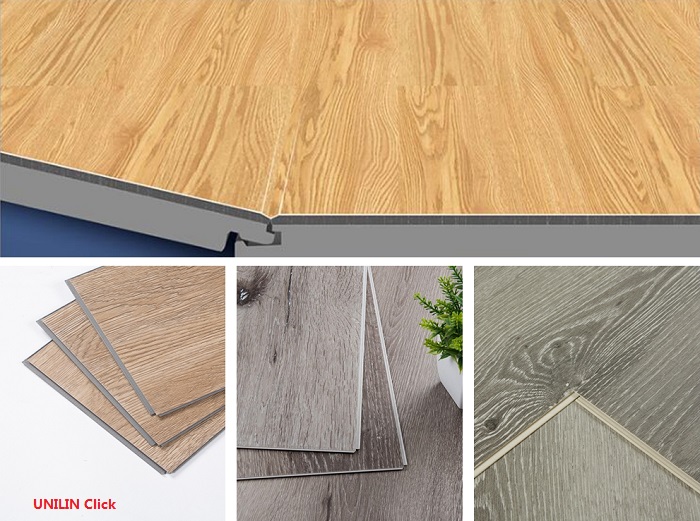

UNILIN (UNIPUSH), Valinge (2G/5G, Drop Click), I4F

1. UNILIN click system: Mainstream of SPC Vinyl Click lock vinyl flooring

2. Valinge 2G Click Lock: Applicable on thin SPC vinyl

3. Valinge 5G click system: Applicable on SPC thicker than 5mm

4. I4F click lock system: economic click system

5. Drop click: Easy Installation

Trimming Process:

UV coating:

Normal PUR coating 1 layer, UV Drying;

Normal PUR coating 2 layer, UV Drying & Air-dry

Ceramic Coating: with Aluminum partition in the coating liquid, makes surface more anti-scratch, better wearing strength, better fireproof characters

Product inspect before sending to customers:

Packaging and storage:

Q&A

1. If the ground floor not smooth, can we install the SPC directly?

With a backing liner (IXPE or EVA) at the bottom of SPC, 2mm height difference in 1sqm of the subfloor is accepted.

2. What is your EIR production process?

We use Hot Press, it is easier to operate, and more accurate between embossing and the colors.

3. What Click System do you suggest?

We have Click system UNILIN, I4F, Valinge. Each click system has its advantages & disadvantages.

UNILIN click is more stable, however it is more difficult installation. And because the depth of the cutting, it is better to use it on plank thickness more than 3.5mm

For 3.2mm SPC, I4F click is recommended.

4. What is the standard for the gap between 2 planks after installation?

It depends on the application area. For hot area, the gap is better 0.05mm – 0.1mm, to avoid plank bending after installation.

5. What is the best thickness of wear layer?

The most competitive thickness of wear layer should be between 0.3mm-0.5mm.

If less thickness, the film is easy to break during production, which make more production waste to increase the production cost. 3C produces 0.15mm-0.7mm wear layer

If 0.7mm, or thicker, the peeling strength is weaker, and the wearing strength is only a little higher than 0.5mm wear layer

6. What kind of UV coating you make?

We make 4 kinds:

Normal UV coating

Self-clean UV coating: Resistant to oil, gasoline and other chemicals

Anti-bacterial UV coating, to avoid bacterial

Ceramic UV coating, to make better wearing and scratch strength

7. What’s the Max thickness of SPC you make?

For one-time extrusion, total thickness 8mm

If you need thicker, we can make 8mm SPC + 2mm LVT

It is difficult for trimming if the SPC is even thicker

8. How is your embossing depth?

We have depth up to 0.3mm for deep emboss.

9. Why is the different color from different shipment?

The color difference of the product cannot be avoided. Generally, the gradient color is easy to control, and the single color is easy to have color difference, so pay attention to labeling the batch, especially the engineering order. Try to avoid mixing different batches.

10. What surface finishes do you provide?

Our surface embossing treatment including: Hand scrap, Crystal, deep embossed, Registered embossed and stone etc

11. What do you mean ABA structure?

ABA SPC main structure from top to bottom: UV layer, Wear layer, Printing Layer, LVT middle layer, SPC rigid core, LVT bottom layer

12. Why ABA?

LVT has more PVC raw material and plasticizer, to make to surface softer and warmer hand feeling. Bottom LVT is used to balance the shrinkage of the middle LVT.

13. Are you trading company or factory?

We are manufacturer of SPC, WPC, LVT, Homogeneous & heterogeneous. At the same time, we are cooperating with some other factories to supply full ranges of flooring products. (WPC decking, Artificial Grass, Accessories, etc)

14. Where is your factory?

We have 3 factories: Anhui, Zhejiang & Shanghai.

Shanghai Factory produce homogeneous & heterogeneous vinyl rolls material. Other 2 Factories are focusing on Plank Flooring.

15. How many colors you have?

We have 2 printing machines to produce some customized film, and we are cooperating with biggest film factories to supply more than 100 designs. Our partners include: LQ, BTF, BORUI, JSJ, YUNJIA, YUNCHANG, etc…

If you need color films from other factories, it is also OK.

16. How many production lines you have?

SPC: 50 extrusion

LVT: 48 hot press

WPC: 10

Homogeneous: 6

Heterogeneous: 6

17. What is your production time?

Normally 30-45 days. For continuous repeat orders, we make stock decoration film and the production time would be much faster.