- 0086 13321818576 (Steven Lee)

- info@3c-floor.com

SPC stone plastic floor: European and American countries call this floor RVP, rigid plastic floor. The lock-type SPC stone plastic flooring is actively promoted and developed at a high speed in domestic and foreign markets.

The composition of the locking SPC stone plastic floor:

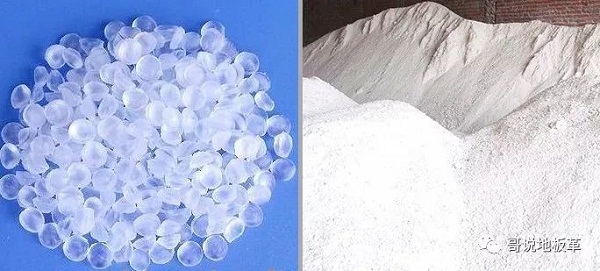

Floor components: PVC resin powder, stone powder, plasticizers, stabilizers, carbon black, the main component is polyvinyl chloride and stone powder.

Structure: From the bottom to the surface, it is composed of PVC base color decoration paper, wear-resistant layer and UV coating.

The lock type SPC stone plastic floor is based on high-tech developed a new type of environmentally friendly floor, with zero formaldehyde, mold, moisture, fire, pest control, easy installation and so on. SPC rigid vinyl floor is made by extruding PVC substrate with extruder and T-shaped die, and using PVC or PVC four-roller calendering machine to wear PVC wear-resisting layer, PVC color film and PVC substrate respectively. , The process is simple, the fit is done by heat, no glue is needed.

Locking type SPC rigid vinyl plank materials use environmentally friendly formula, does not contain heavy metals, phthalates, methanol and other harmful substances, in line with EN14372, EN649-2011, IEC62321, GB4085-83 standards. In Europe and the United States developed countries and the Asia Pacific market is very popular.

With its outstanding stability and durability, stone-plastic flooring not only solves the problem of damp and deformed wood flooring, but also solves formaldehyde problems of other decoration materials. It is available in a variety of color patterns for indoor decoration, hotels, hospitals, shopping malls and other public places.

Production process of lock-type SPC stone plastic floor:

Process 1: Mixing

According to the ratio of raw materials, automatic metering → high-speed mixer hot mixing (heat mixing temperature: 125 °C, the role is to make all kinds of materials evenly mixed, remove the moisture in the material) → into the cold mix (to reduce the temperature of the material to prevent caking and discoloration, Cold mix temperature: 55°C) → Cool the mixed material;

Process 2: Extrusion

Add a twin-screw extruder, heat extrusion → enter the sheet die extrusion molding, forming the film

The material is passed through a four-roll calender, the base material is thickened, the color film is applied, the wear-resistant layer is applied, cooling, and cutting.

Process 3: UV tempering

Surface UV→tempered (tempered hot water temperature: 80~120°C; cold water temperature: 10°C)

Process 4: slitting

Cutting → slotting, trimming, chamfering → inspection → packaging