- 0086 13321818576 (Steven Lee)

- info@3c-floor.com

SPC luxury vinyl flooring has been fully recognized by the market and is widely used in offices, hotels, restaurants, teaching and home improvement places. However, due to the lack of experience of participants in sales and construction, the user experience is not satisfactory. Now let's briefly describe the problems of installation and use.

1. Installation

1). The flatness of the old ground (tiles, terrazzo, wood floor, etc.) must meet the requirements. Uneven paving of the ground will cause the SPC click vinyl floor planks to have ups and downs, tripping, warping, and board breakage. The thinner the floor thickness and the larger the version, the higher the level of ground flatness is required. Before paving, a 3-meter ruler can be used to detect the ground height difference. If leveling is determined to be required, the plan should be selected according to the site conditions:

A. Fine leveling--Cement-based self-leveling (about 3-5mm thick) can be used, which has high cost, good strength, and is not afraid of water.

B. Thick layer leveling--Gypsum-based self-leveling (above 1 cm) can be used, which is economical and applicable, with moderate strength and fear of water (not recommended for wet ground).

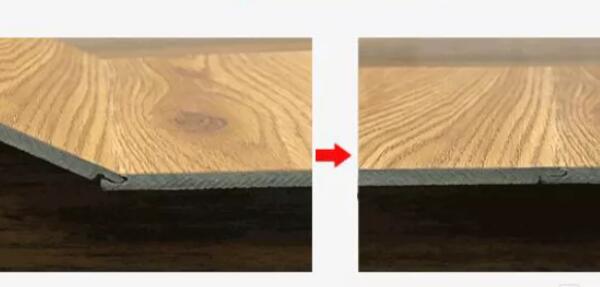

2. When installing the rigid LVT vinyl flooring below 8mm thickness, you can add a moisture-proof film (or shock-absorbing pad) with a thickness of ≤ 2mm, but thick foam floor mats are prohibited. Because the thin SPC floor will transmit the surface load pressure downwards, the texture of the floor mat is soft and cannot withstand the concentrated point load, and the feet of tables, chairs, cabinets, etc. are easy to compress and deform after being pressed, causing the SPC vinyl flooring planks to deform due to the foundation gap , Fracture, tripping and other issues.

3. The construction must be carried out by experienced construction personnel. When installing SPC rigid core vinyl flooring plank, you should determine the appropriate reserved expansion joint size according to the floor thickness, material, area, etc., the degree of tightness of the buckle between the floors, the direction of paving, the method of edge closing, and the treatment of joints, all of which require rich experience. To complete.

2. Usage

1. The wear-resistant layer of the SPC flooring is usually made of PVC+UV coating material. Its wear resistance is not tested by extreme damage tests with nail brushes, sharp objects, etc., but simulated indoor human foot soles and floor in the laboratory. The frictional environment is measured by the number of revolutions when the round steel wheel rolls on its surface to wear through. The higher the number of revolutions, the better the wear resistance, and the thicker the wear layer, the better the wear resistance. In the market, using extreme destructive methods to detect floor abrasion resistance is just a marketing method. Either the price is not close to the people, or it is not mass-produced. Besides, in life, who would wear shoes with metal soles every day at home?

2. The feet of the metal bed (cabinet, table, chair) should be separated from the floor with rubber mats to reduce the impact on the floor to avoid scratches or rust. When moving large objects on the floor, it is forbidden to push directly on the ground, and move it off the ground (lift or pulley).

Three, summary

A good user experience is inseparable: good products + good installation + good maintenance.

Our regular thickness of vinyl planks is 3.5mm-8mm., any query, pls freely contact us as below:

Vera Luo

Tel: +86 13701754305

Email: vera@3c-floor.com