- 0086 13321818576 (Steven Lee)

- info@3c-floor.com

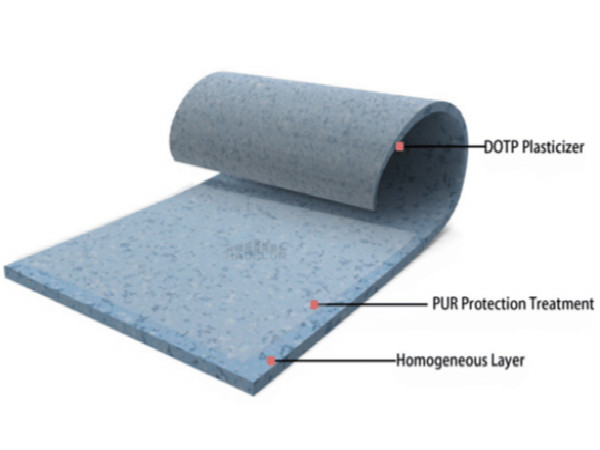

Homogeneous PVC floor is a highly wear-resistant PVC floor made of pure PVC with other materials. How can we identify the quality of homogeneous PVC flooring? In general, we can use the following common knowledge of homogeneous and thorough PVC flooring to distinguish the quality of the floor.

1. Grade of wear-resistance

Homogeneous through-floor is composed of PVC and fillers and plasticizers. It is not a pure PVC structure. You can easily distinguish the grade of the wear-resistance. The harder it is, the less the second-filled material is in the floor.

According to European standards, the grade of wear resistance for PVC floors is T, P, M, F in order from high to low, and T is almost zero wear. Therefore, the floors we commonly see are all below grade T. Strictly speaking, T level can only appear in multilayer composite PVC floors with pure PVC wear-resistant layers.

In addition, the higher the wear resistance level, the greater the PVC content. In contrast, the lighter the weight per unit area, the higher the cost. Therefore, the unit area we often mention in some bidding projects is less than. This is actually a requirement for product quality.

2. Visual observation

Looking at the floor from the cross-section of the floor, if the material of each position of the floor interface is the same, this is a good floor from a good factory.

If the middle layer looks similar to the powder state, it proves that the stone powder content is too high;

If there are pores in the middle layer, it proves that the floor is not dense enough;

In winter, we can also bend the floor, and the quality of the broken floor is not good.

3. Whether the floor has directionality

Under the same level and condition, the quality of non-directional homogeneous PVC floor is slightly higher.

4.Surface PU, PUR treatment

PU is the surface treatment of polyurethane. Since the floor is composed of PVC and fillers and plasticizers, there are inevitable capillary holes on the surface, so a layer of polyurethane is sealed on the surface to block the capillary holes to prevent the penetration of dirty objects. Into the floor. But this is limited to surface treatment. After the surface layer is worn, the PU treatment effect disappears.

PUR is the deep strengthening treatment of polyurethane. The calendering process is used to penetrate the polyurethane to the entire thickness of the floor. Even if there is continuous wear, the dirt is difficult to penetrate. This technology is commonly used in European production of high-grade homogeneous cores Floor manufacturers.