- 0086 13321818576 (Steven Lee)

- info@3c-floor.com

1. Requirements before installation

Ground requirements before installation of SPC stone-plastic lock floor: leveling work must be completed.

Ground flatness: The slope is less than 3 mm for a distance of 1 meter.

The SPC click floor can be installed on the existing tile floor, old wooden floor, terrazzo floor, supporting floor heating, cement floor, and staircase floor; as long as the floor is flat, it can be paved.

SPC stone plastic lock floor installation construction tools: tape measure, cutting machine, hammer, knock block, glass glue.

2. Construction management process of SPC stone-plastic lock floor installation project:

The first step: clean the foundation ground.

Make sure that the ground does not have a lot of sand, so as not to affect various minor problems in the later use of the floor.

Step 2: After the ground is cleaned, spread moisture-proof cotton.

reason:

1. Because the rigid click lock flooring is already moisture-proof, the reason for laying moisture-proof cotton now is to separate the ground from the lock floor to prevent some fine sand on the ground from being cleaned and "creaking" when walking. sound;

2.Everyone knows that the lock floor is thinner than the wooden floor and the composite floor. If you spread it directly on the ground, because it is thin, you will feel the effect of stepping on the tiled floor when you walk. In addition to the appearance is better, but the foot feels too hard to step on, then the moisture-proof cotton can also improve the comfort of the foot.

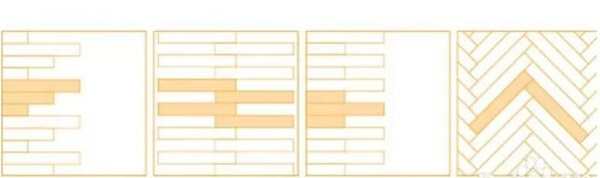

The third step: choose paving method:

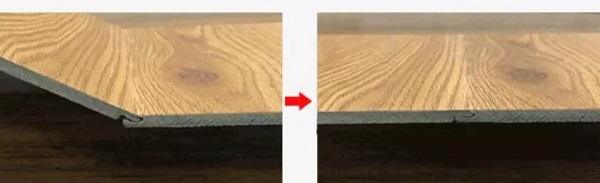

Step 4: After choosing the paving method, start laying at a right-angle wall. After aligning the buckles, as shown in the picture below, the 45-degree buckle is embedded, and the vinyl plank flooring is laid without a wooden frame; it can be installed directly, leaving a gap of 10 mm between the wall and the board.

Step 5: After paving the entire ground, enter the final process. If you need to install the anchor line after finishing the lock floor, install the anchor line directly. If there is no anchoring line installed, directly apply glass glue to close the mouth. (It is the gap between the wall and the lock floor and the wall. Use glass glue to close it, which will look more beautiful.)

3. Construction points before installation of SPC vinyl plank floor:

1. 10 mm expansion joints should be reserved before walls, door frames and SPC floors. For rooms with an area greater than 100 square meters (length and width more than 10 meters), there should be an expansion gap. For corridors longer than 15 meters, expansion joints should be set at about 10 meters. It is necessary to keep a gap of no less than 13 mm between the door and the ground to ensure that the normal door switch will not wear out with the ground.

2. It can be used on the surface of cement floor and ceramic tile or the sub-floor where moisture penetrates, but the next layer must have a moisture-proof mat.

3. After the product enters the installation site, it should be placed in a standard ventilated, backlit, and non-humid place. The product must be stored at room temperature for at least 48 hours before installation without opening the package.

4. Be sure to place heavy objects (such as a bundle of wooden boards) at the newly connected place to make it stable.

5. Reserve a height: The customer should reserve the required height according to the actual contact height of the ground and the SPC luxury vinyl flooring planks and tiles, especially the door cover, wall corner, heating cover and other irregularities and details. It should also be possible. Analysis and processing.

Fourth, the effect picture after installation: