- 0086 13321818576 (Steven Lee)

- info@3c-floor.com

1. Loss: The loss of the floor varies according to the size, shape, and shape of the room (such as the floor, partition, etc.). Generally speaking, the room is square and large, and the loss is small, generally less than 5%. 3 - 5%, the loss of individual shaped structures may exceed 5%.

2. 8-12 mm expansion joints should be reserved around the floor. The LVT floor runs parallel to the light.

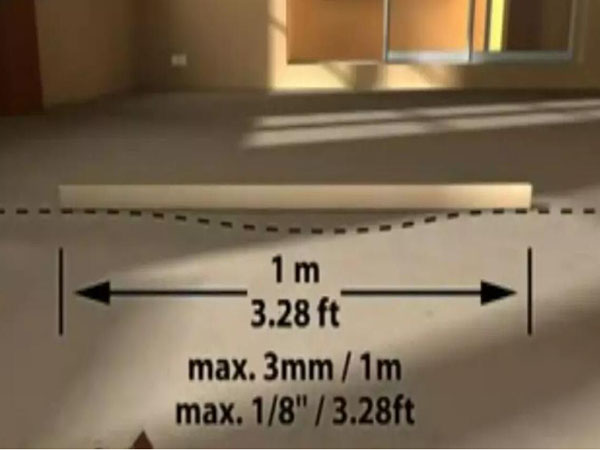

3,Requirements for the ground: clean (no obvious construction waste, etc.), dry (refer to ground moisture should be less than 20%, no wet or leaking), leveling (detecting ground flatness at 2M by foot, relying on the ruler and the ground The maximum string height should be <3mm) and firm (the ground foundation strength and thickness should comply with the house acceptance regulations).

4. The cement LVT lock floor should not be dusty, the water content should be less than 5% (it should be no more than 2% for the geothermal system), and the wooden floor should be 6%-10%.

5.The product needs to be allwed to stand at the construction site for more than 48 hours to achieve the right temperatrure at the site.In winter (below 20 degree), it is necessary to turn on air conditioner for 48 hours,and the temperature is within 25 degrees plus or minus 3 degrees.

6.The long-term room temperature must be below 40 degerees and the installation environment (including surface and indoor) should be controlled at 18-22C.. The maxium relative humidity of the room before installation is not higher than 60%.It is not suitable for bathroom,tolit,saunna and environment. Installation in harsh public is not suitable for laying under the condition that the bottom of the stone-plastic lock floor is too soft.

7.Inter-segement problem:The maximum legth of the lock-type floor is 7-8 meters.The length of the lock is requiired to be cut off.