- 0086 13321818576 (Steven Lee)

- info@3c-floor.com

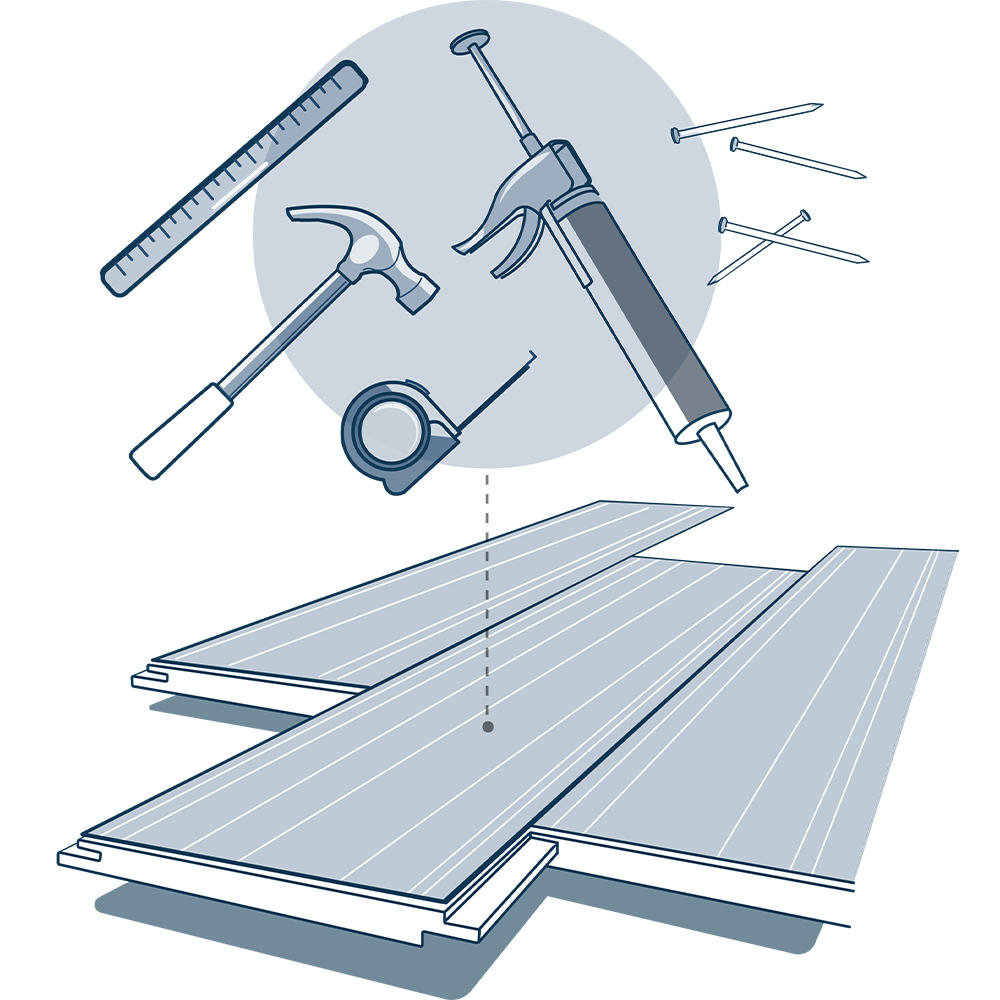

Before you begin your SPC vinyl flooring installation project, it's essential to gather the necessary tools to ensure a smooth and efficient process. Here's a list of the tools you'll need:

1. Tape Measure: A reliable tape measure is crucial for accurately measuring the room dimensions and ensuring you order the correct amount of SPC flooring.

2. Utility Knife: A sharp utility knife is essential for cutting SPC planks to size, especially when you reach the edges and corners of the room.

3. T-Square or Straight Edge: A T-square or straight edge helps you make precise cuts, ensuring that your SPC planks fit seamlessly against walls and obstacles.

4. Pencil or Chalk Line: Marking planks and subfloor guidelines is easier with a pencil or chalk line. It helps you maintain proper alignment during installation.

5. Safety Glasses and Ear Protection: Safety should always be a priority. Wear safety glasses to protect your eyes and ear protection if you're using power tools.

6. Crosscut Saw or Circular Saw: A crosscut saw or circular saw with a fine-toothed blade is useful for making straight cuts on SPC planks quickly and accurately.

7. Pry Bar: A pry bar can assist in removing baseboards or existing flooring materials without damaging them.

8. Rubber Mallet: A rubber mallet is handy for gently tapping SPC planks into place, ensuring a snug fit.

9. Spacers: Spacers help maintain the necessary expansion gap between the SPC flooring and walls or obstacles. They ensure the flooring can expand and contract with temperature changes.

10. Adhesive (for Glue-Down Installation): If you're opting for the glue-down installation method, you'll need the recommended adhesive and a trowel for application.

11. Underlayment (if required): Check the manufacturer's recommendations. Some SPC flooring products may require an underlayment, in which case you'll need it for installation.

12. Double-Sided Tape or Adhesive Tabs (for Loose Lay Installation): For loose lay installation, you may need double-sided tape or adhesive tabs to secure the flooring along the edges and seams.

13. Transition Strips: Transition strips are essential for creating a clean, finished look where the SPC flooring meets different types of flooring or transitions between rooms.

14. Dust Mask and Respirator: When cutting or handling SPC planks, it's advisable to wear a dust mask or respirator to protect against inhaling dust particles.

15. Cleaning Supplies: Have cleaning supplies, such as a broom, vacuum cleaner, and mop, on hand to keep the installation area clean and free of debris.

By having these tools ready before you begin your SPC vinyl flooring installation, you'll be well-prepared to tackle the project efficiently and with confidence.

Work Out the Amount of Flooring Required

Step 1: Measure the Room

Start by measuring the length and width of the room where you plan to install the SPC flooring. Make sure to measure in inches or centimeters for accuracy.

Step 2: Account for Waste

To ensure you have enough material, add 10% to 15% to your measurements to account for waste and any pattern matching that may be required.

Acclimatise the SPC Vinyl Planks

Before installation, SPC must acclimatise to the area you will install it in. Do not store boxes on their sides; keep them flat and level. During acclimatisation, you should turn on the heating or air conditioning to maintain a temperature of 41 °F (5 °C) to 140 °F (60 °C).

The flooring should be acclimated and installed in a temperature-controlled environment, with temperature fluctuations permitted only after the installation is complete.