- 0086 13321818576 (Steven Lee)

- info@3c-floor.com

Short answer: LVT (Luxury Vinyl Tile) is a multi-layer vinyl flooring product that realistically mimics wood, stone or tile. It offers high durability, often waterproof performance, and flexible installation options — making it a top choice for both residential and commercial projects.

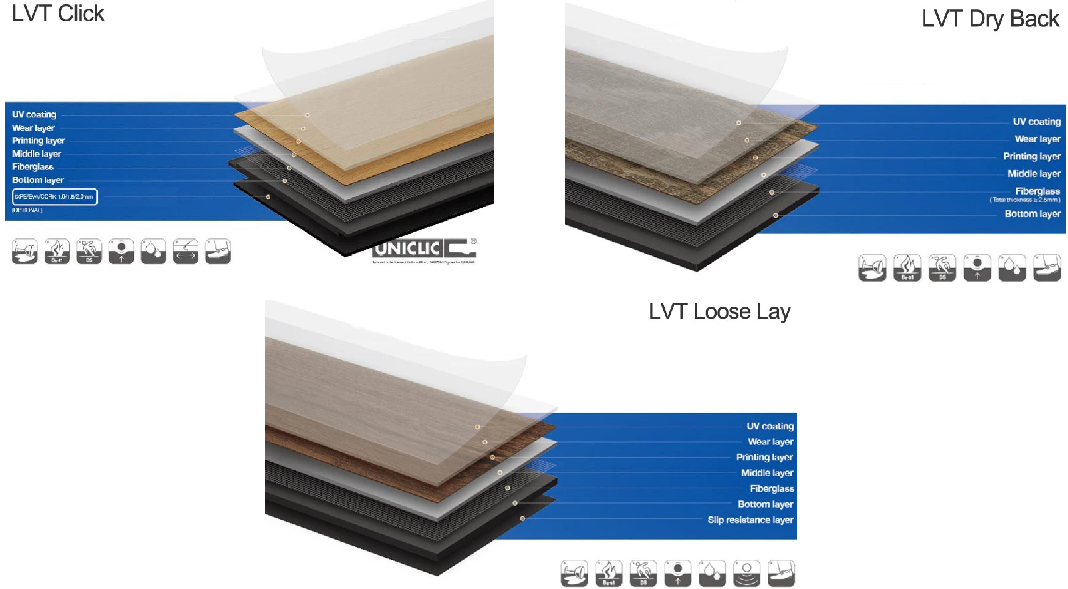

LVT floor is usually composed of a multi-layer structure, including UV paint layer, wear-resistant layer, color film layer, bottom material layer and so on. It is mainly composed of PVC resin and stone powder. The production of LVT flooring is usually made of finished flooring by hot pressing.

1. Green environmental protection: The main raw material polyvinyl chloride is environmentally friendly and non-toxic renewable resources.

2. Waterproof floor: The surface has a special LVT wear-resistant layer, high wear-resistant revolution, long service life.

3. High elasticity and impact resistance: soft texture, good elasticity, can reduce the impact on the foot.

4. Fire retardant: fire index up to B1 level, out of fire.

5. Easy maintenance: easy to clean and maintain.

6. Waterproof and moisture-proof: The main component vinyl resin has no affinity with water and is suitable for humid environments.

LVT flooring is suitable for a variety of places such as homes, offices, shopping malls, schools, etc., and is popular for its durability, easy maintenance and diverse design.

LVT (Luxury Vinyl Tile) is an engineered vinyl flooring made of multiple layers designed for performance and appearance. Typical layers include: UV protective coating, wear layer (transparent and protective), high-definition decorative film (wood/stone visuals), a resilient vinyl or rigid core (SPC/WPC options), and a backing layer that adds stability and acoustic properties.

LVT can be produced in tile (square/rectangular) or plank formats (LVP — Luxury Vinyl Plank). Modern LVT comes in several core constructions:

This guide focuses on all LVT variations and helps you understand which type suits your project.

High-quality LVT uses a wear layer (0.2–0.7 mm typical) with UV-cured coatings and optional polyurethane (PU) or enhanced treatments for scratch and stain resistance — ideal for residential and commercial traffic.

Many LVT options (especially SPC) are 100% waterproof and will not swell like solid wood when exposed to moisture — perfect for kitchens, bathrooms, basements and rental units.

Modern printing and embossing technologies create photorealistic wood grain and stone textures, with registered embossing that matches the visual grain for a natural look.

With integrated backing or optional underlay, LVT provides improved comfort underfoot and sound reduction compared to hard tile or stone.

Available installation methods: glue-down, loose-lay, and click-lock floating systems. Click systems shorten installation time and are favorable for DIY and fast commercial turnarounds.

Below is a typical specification table you can adapt for specific SKUs. Always include product code, thickness, wear layer and recommended usage on product pages for Google rich results.

| Item | Typical Value / Range | Notes |

|---|---|---|

| Overall Thickness | 2 mm — 8 mm (commonly 4–6 mm) | Thicker options provide better comfort & flatness. |

| Wear Layer | 0.20 mm — 0.70 mm (20 — 70 mil) | Higher wear layer = better durability for commercial use. |

| Plank Size (example) | 1220 × 180/220 mm, 1524 × 228 mm | Various formats available (wide plank, long plank). |

| Tile Size (example) | 457 × 457 mm, 600 × 300 mm | Stone look tiles often use smaller tile sizes. |

| Core Type | Flexible vinyl / SPC / WPC | SPC = rigid & stable; WPC = cushioned underfoot. |

| Surface Finish | PU / UV / SPC matte / gloss | Anti-slip and scratch resistant finishes available. |

| Traffic Rating | Residential to heavy commercial (check EN/ASTM ratings) | Specify rating per SKU (e.g., commercial class 33). |

| Fire Rating | B1 / Class C (varies) | Check local fire code compliance. |

| VOC Emissions | Low VOC / FloorScore or equivalent | Important for indoor air quality. |

| Underfloor Heating | Compatible if rated (check max surface temp) | Manufacturer to provide thermal resistance data. |

LVT flooring is versatile. Below are common use cases and suggested product types:

Tip: On product pages, show “ideal room use” icons and specify SKU recommendations for each application to help buyers and improve conversion.

3C-Floor Co., Ltd. is an experienced manufacturer of LVT, SPC and WPC flooring. With advanced production lines, ISO quality control and export experience, 3C-Floor serves global distributors, interior designers and project contractors.

Capabilities & credentials:

If you want company-specific SEO: include pages such as “About 3C-Floor”, “Factory Tour”, “Certificates” and link to product category pages — these internal links help Google understand site structure.

Proper installation is critical for performance and longevity. Follow these precautions:

3C-Floor exports LVT flooring globally. Major markets include:

We provide export packing, customs documentation and CIF/FOB shipping terms. For project shipments, contact our export team for lead times and MOQ details.

A: LVT stands for Luxury Vinyl Tile. It is a multi-layer vinyl product that mimics natural materials with superior durability and water resistance compared to traditional wood.

A: Many LVT products (especially those with SPC cores) are 100% waterproof. However, correct seam installation and transitions are important to maintain waterproof performance.

A: Yes — often over well-bonded ceramic tile or concrete — provided the surface is even and the substrate meets manufacturer flatness and moisture limits.

A: With proper installation and maintenance, residential LVT often lasts 15–25 years; commercial grade with thicker wear layers can last longer depending on traffic.

A: LVT/LVP are luxury vinyl in tile/plank forms. SPC (Stone Plastic Composite) is a rigid core variant of luxury vinyl. Sheet vinyl is a continuous roll product that is thinner and less textured than LVT.

Use these phrases naturally in product pages, image alt text, FAQs and blog posts to strengthen topical relevance on Google.

LVT is an excellent choice when you need the look of natural materials combined with durability, waterproof performance and easier maintenance. Select the right core (SPC/WPC/flexible), wear layer thickness and finish for your application, and follow professional installation guidelines to ensure long service life.

Want samples? Contact 3C-Floor for free samples, technical data sheets, and a tailored quote for your project: info@3c-floor.com