- 0086 13321818576 (Steven Lee)

- info@3c-floor.com

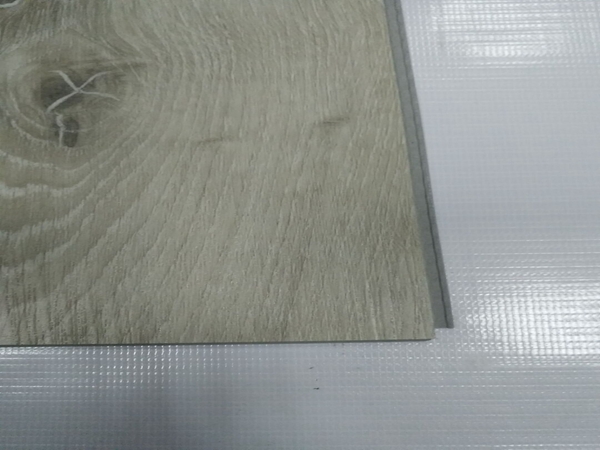

Looking at the structure of the spc lock floor first, the UV layer: This layer determines the anti-fouling ability of the floor and the ability to protect the color film layer (anti-UV color change). The process will pass at least 2 UVs; wear-resistant layer: basically Determines the service life of our floor, it is also the most critical layer to determine the wear resistance of the floor, the thickness is generally 0.3mm to 0.7mm; color film layer: it is the floor pattern and color we can directly see; spc base Material: It is a mixture of polyvinyl chloride and calcium powder; optional additional layer: it mainly plays a role in increasing sound insulation and comfortable feet. The spc lock floor not only increases the wear-resistant layer in particular, the UV layer also protects the floor to a certain extent and increases the service life of the floor.

Looking at the production process of the spc embossed flooring, the main raw material of SPC is polyvinyl chloride resin, mixed with calcium powder, and the substrate is extruded by an extruder combined with a T-type die. The three-roller or four-roller calender is used to wear-resistant PVC. Layer, PVC color film and SPC flooring material are made by heating and laminating at one time, and are products without using glue. From the point of view of raw materials, spc lock floor is more solid and abrasion-resistant than wood materials, and the one-shot molding process also increases the stability of the floor structure.