- 0086 13321818576 (Steven Lee)

- info@3c-floor.com

ESD vinyl flooring is widely used in clean rooms, manufacturing & assembly workshops of electronic products, hospitals, data centers & computer rooms, and other areas that require an anti-static environment. There are two kinds of ESD vinyl flooring, ESD tile and ESD sheet.

Both tile and sheet are homogeneous structures, and electronic resistance can meet both conductive(10^4-10^6Ω) and static-dissipative(10^6-10^9Ω).

What is the difference between ESD tiles and ESD sheet?

1. Production Processes

The raw materials of tile and sheet are almost the same; materials include polyvinyl chloride resin, conductive materials, stabilizers, plasticizers, pigments, and other auxiliary materials. But their production processes and equipment are entirely different.

2. The implementation of conductivity.

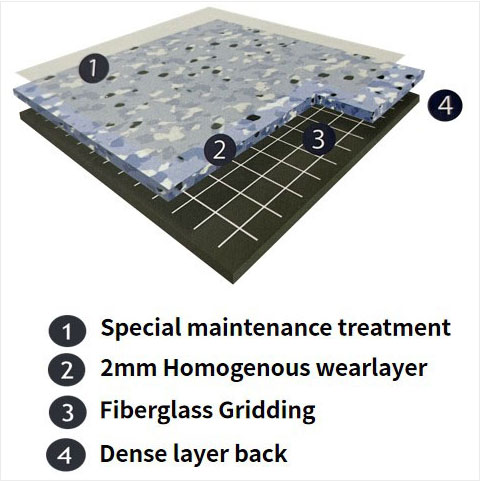

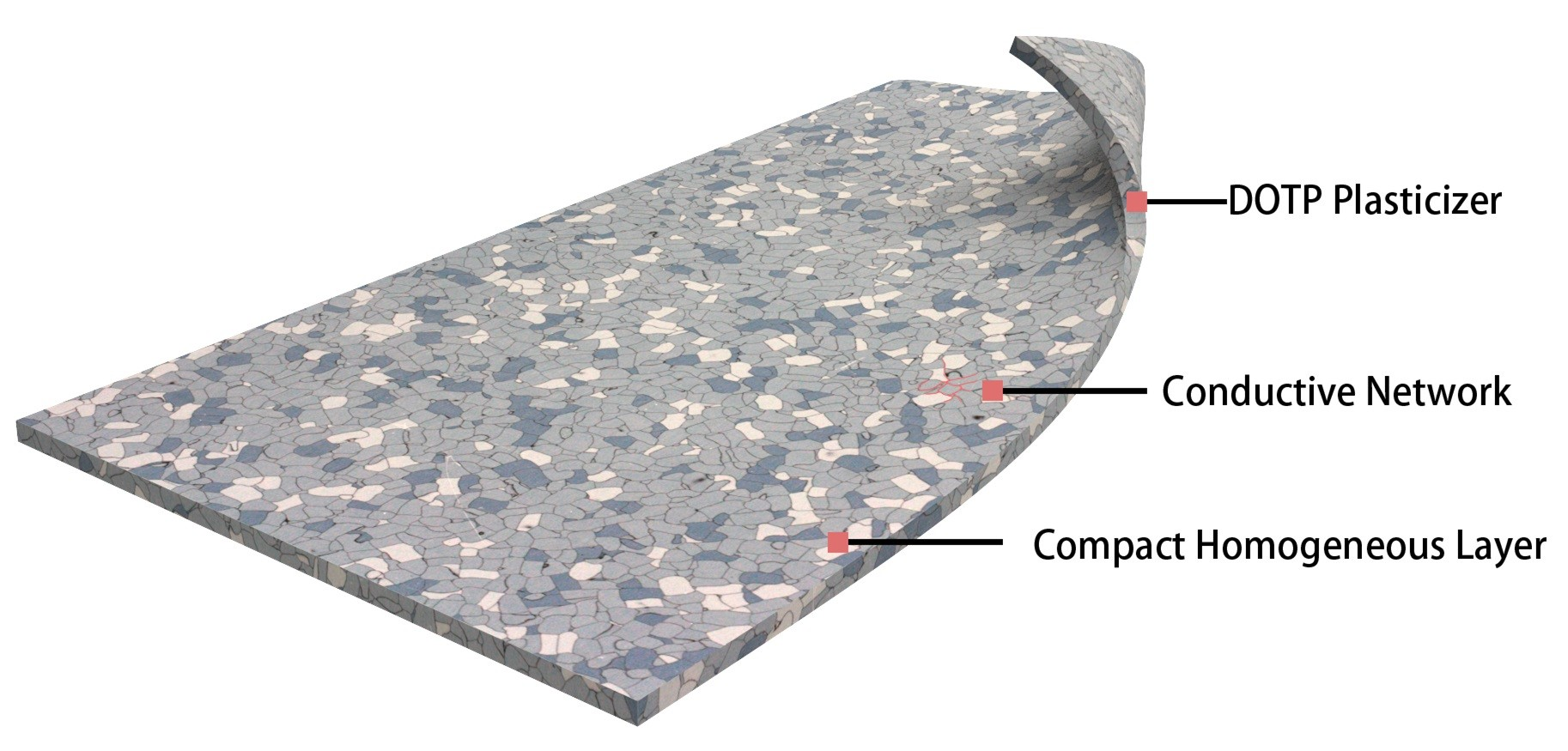

Tiles utilize a conductive network electrostatically formed by the interface of plastic particles. It ensures permanent conductive properties. The ESD sheet inserts carbon-encapsulated granules throughout the whole thickness, and a conductive backing is attached, providing optimum and consistent conductive properties.

3. Spec

ESD tile :

Size: 600×600mm, 610×610mm, 900×900mm,

Thickness can be 2mm, 2.5mm, and 3mm.

ESD sheet:

Size: 2×20m, 2×15m,

Thickness: 2mm, 2.5mm, 3mm.

4. Installation

The installation tools and accessories for tiles and sheets are the same. The accessories include conductive glue, welding rod, copper tape, and so on. Due to the different sizes, the installation steps are different. Compared with tiles, the single area of the sheet is much larger, and the installation professionalism is higher. Check specific installation processes as below videos.

5. Price:

The price of the sheet is higher than the price of the tile.