Product Introduction

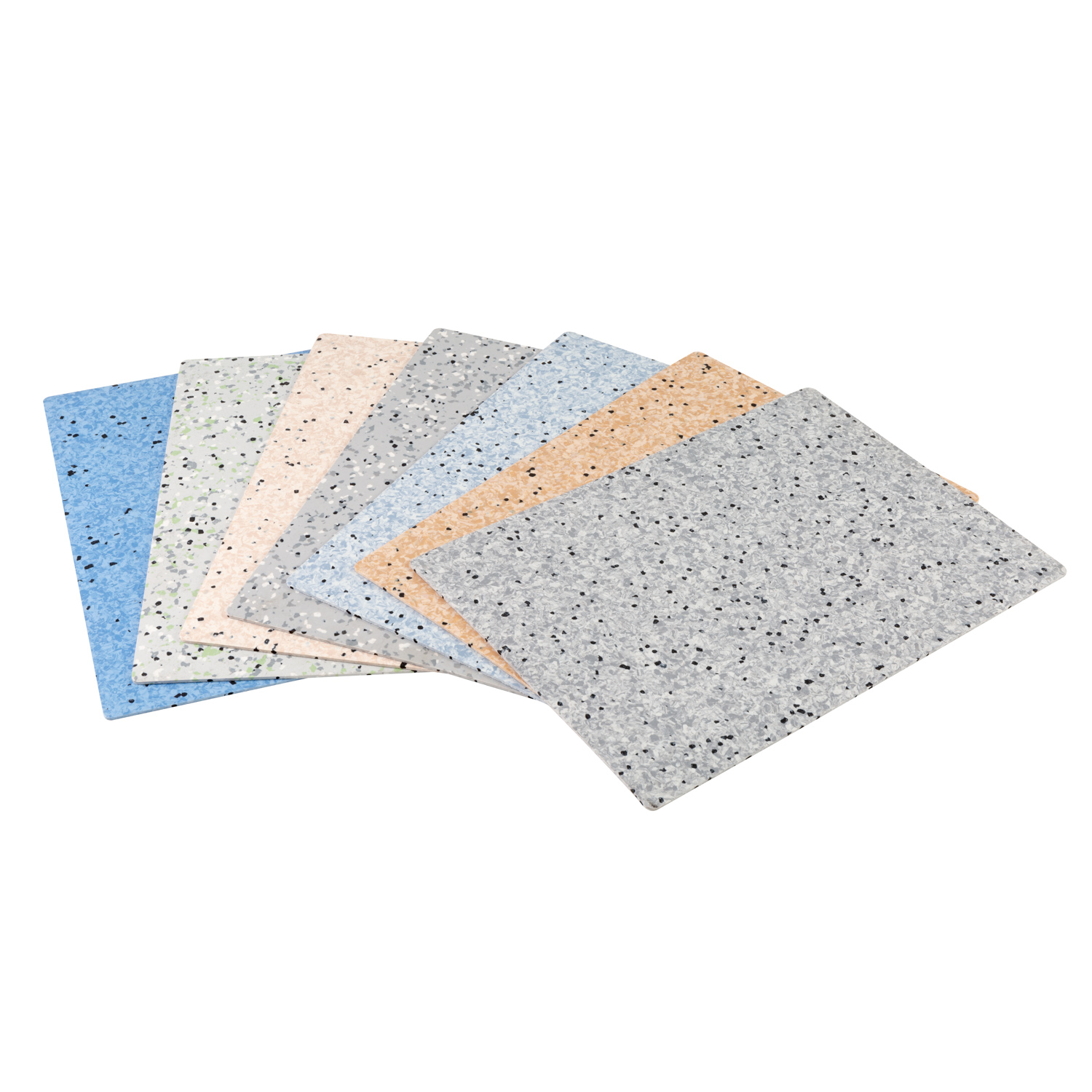

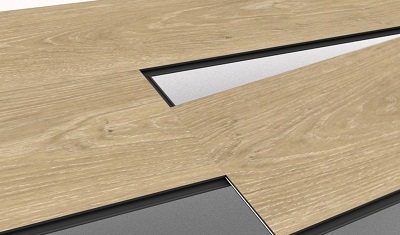

PVC vinyl flooring has become the go-to surface for building owners who demand durability, water resistance, and design flexibility. At 3c-floor we manufacture multiple PVC product families — including rigid SPC options, luxury vinyl tile (LVT), glued sheet vinyl and loose-lay vinyl planks — each engineered for different project needs.

Our manufacturing systems combine high-quality PVC compounds with advanced surface treatments to create floors that resist scratches, stains, and heavy rolling loads while providing authentic wood and stone visuals. For architects specifying resilient surfaces, our catalog provides technical sheets, sample kits and project references to simplify selection.

Related product: learn more about our PVC flooring range — a rigid, waterproof PVC composite ideal for heavy commercial traffic and areas prone to moisture.

Product Features — What Makes Our PVC Vinyl Special

Performance & Durability

- Waterproof construction: PVC products resist moisture and are dimensionally stable in wet environments.

- High wear layers: Commercial-grade wear films (0.3–0.7 mm) protect against abrasion and retain appearance.

- Scratch & stain resistance: Superior surface treatments prevent marking and simplify maintenance.

- Impact resistance: Formulations optimized to withstand rolling loads and heavy furniture in retail or hospitality settings.

Design & Environment

- Authentic visuals: High-resolution printing and synchronized embossing replicate hardwood, stone and concrete looks.

- Acoustic options: Integrated or optional underlays reduce sound transmission — ideal for multi-level buildings.

- Low VOC: Formulated to meet stringent indoor air quality standards for commercial interiors.

- Recyclable components: Manufacturing processes minimize waste and include recycling programs for production offcuts.

Product Specifications

| Attribute | Typical Specification |

|---|---|

| Core Type | Rigid SPC (stone-plastic composite), WPC (wood-plastic composite), Flexible PVC sheet |

| Plank Size (examples) | 1220×180 mm, 1220×220 mm, 1524×228 mm; LVT 600×600 mm tiles |

| Thickness | 2.0 mm - 8.0 mm (product-dependent) |

| Wear Layer | 0.2 mm — 0.7 mm (residential to heavy commercial) |

| Finish | UV-cured PU / PE lacquer / Ceramic reinforced surface |

| Installation | Click-lock, glue-down, loose-lay |

| Underlay | Integrated IXPE, cork, or separate acoustic underlay options |

| Fire Rating | Bfl-s1 / Class B / local equivalents |

| Warranty | Residential 10-25 years; Commercial 5-15 years (model dependent) |

All specifications are model-dependent — contact 3c-floor with your project code for exact datasheets and test reports.

Product Application — Where PVC Vinyl Excels

PVC vinyl is versatile and suitable for many sectors. Typical applications include:

- Retail environments: Durable finishes handle high footfall, trolleys and regular cleaning regimes.

- Hospitality: Restaurants and hotels benefit from stain-resistant surfaces and authentic wood visuals.

- Healthcare: Hygienic, easy-to-clean surfaces that meet infection-control cleaning protocols.

- Education: Classrooms, corridors and multipurpose halls where durability and acoustic performance are needed.

- Offices: Quiet, attractive surfaces with good underfoot comfort for open-plan workspaces and meeting rooms.

- Residential: Kitchens, bathrooms, basements and living areas where waterproof performance and style matter.

Why Choose 3c-floor — The Manufacturer Advantage

As an experienced PVC vinyl flooring manufacturer, 3c-floor merges factory control with customer-focused services:

- Factory direct pricing: Short supply chain and competitive EXW/FOB pricing for bulk projects.

- Strict QC: Batch inspection, color consistency checks, and third-party testing available on request.

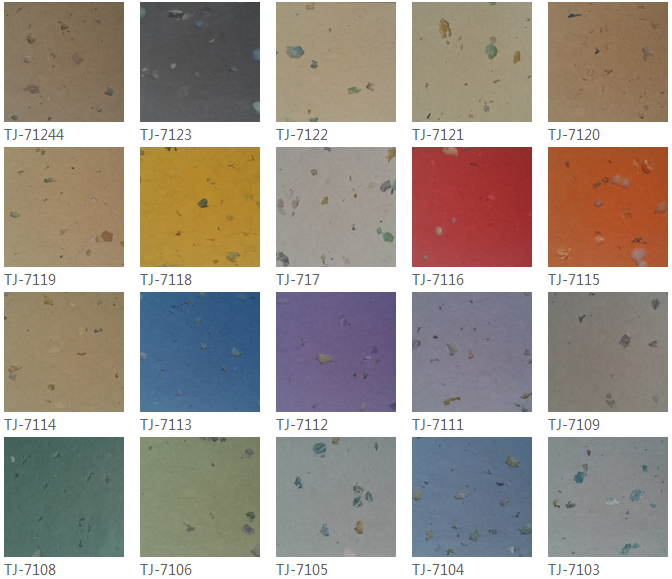

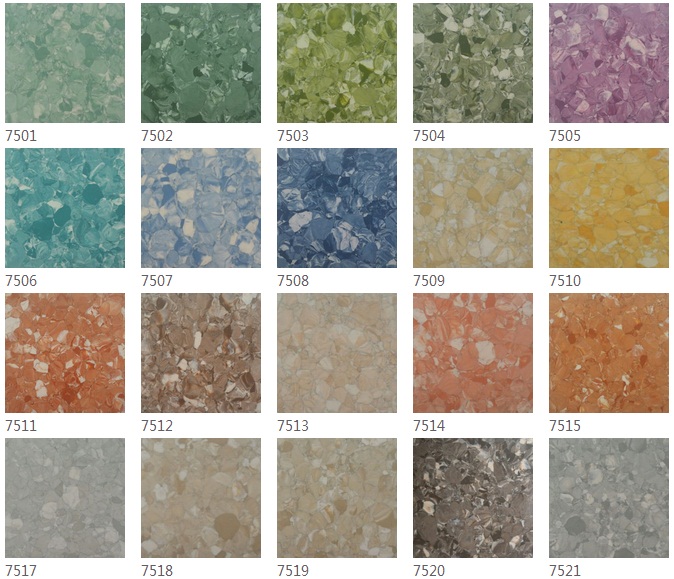

- Customization: Custom colors, plank sizes, and textured embossing options for brand-unique installations.

- Technical support: Specification assistance, NBS/CSI compatible documentation, and site installation guidance.

- Global shipping: Experience exporting to international markets; consolidated logistics for multi-site rollouts.

3c-floor also partners with designers and architects to produce sample suites and mock-ups, allowing stakeholders to confirm visual selections before full procurement.

3c-floor Company Profile

3c-floor is a vertically integrated manufacturer of resilient flooring products with decades of industry experience. We focus on supplying specification-grade surface materials to distributors, contractors, and end-users worldwide. Our facilities combine modern extrusion, lamination and coating lines with rigorous environmental and quality systems.

Certificates & Compliance

We provide a range of certificates to support procurement and compliance requirements:

- ISO 9001: Quality Management System

- ISO 14001: Environmental Management (selected product lines)

- CE / UKCA (where applicable) and regional conformity documents

- Fire reaction test reports (Bfl-s1 or regional classifications)

- VOC / Emissions reports (compliant with relevant indoor air quality standards)

- Slip resistance and wear test reports (EN / ASTM standards)

For project tenders that require specific certificates, include your procurement code in the quote request and our sales team will attach the relevant documentation.

Related Product Lines

Besides our core PVC vinyl range, 3c-floor supplies rigid core solutions. For projects requiring a rigid composite core with superior indentation resistance, explore our SPC flooring product family which is frequently specified for heavy-traffic retail and transport hubs.

Installation Precautions & Best Practices

- Acclimation: Store panels on site for at least 48 hours in the conditioned space to minimize expansion/shrinkage after installation.

- Subfloor preparation: Ensure subfloor is flat, clean, dry and structurally sound. Concrete slabs should meet moisture vapor emission limits; use primers or barriers if necessary.

- Level tolerance: Maximum deviation typically 3 mm per 2 m — check product datasheet for exact requirements.

- Installation method: Choose between click-lock, glue-down or loose-lay based on area use, rolling loads, and acoustic requirements.

- Movement joints: Provide expansion gaps at perimeter and fixed points; follow our installation guide for recommended gap sizes.

- Underfloor heating: Many PVC vinyl products are compatible with radiant systems if maximum surface temperatures are observed (usually ≤27–29°C). Request technical confirmation per SKU.

- Cleaning after install: Remove adhesives, residue and construction dust with manufacturer-recommended cleaners before opening the space to occupants.

For commercial projects we recommend using installers with proven experience in resilient floor systems. 3c-floor can make installer recommendations and provide on-site technical support where required.

Sold to Countries & Global Reach

3c-floor exports PVC vinyl products to a wide international network. Representative markets include:

- North America (USA, Canada)

- Europe (EU countries, UK)

- Middle East & GCC

- Asia Pacific (Australia, New Zealand, Singapore, Japan, South Korea)

- Latin America

- Africa (selected distributors)

For large-scale or multi-site rollouts, we offer coordinated logistics, palletized packaging, and consolidated shipments to reduce per-site handling. Contact our export team for lead times and freight quotes.

Frequently Asked Questions

What is the difference between PVC vinyl and SPC?

PVC vinyl refers to a family of resilient flooring made from polyvinyl chloride; these include flexible sheet vinyl, LVT and some plank systems. SPC (stone-plastic composite) is a rigid core variant where a mineral-filled core provides extra dimensional stability and impact resistance. Choose PVC vinyl for comfort and design variety; choose SPC for maximum rigidity and heavy-load performance.

Are PVC vinyl floors waterproof?

Many PVC vinyl products are waterproof at the plank or tile level. However, overall waterproof performance depends on installation details: seam treatment, transitions, and subfloor moisture management. For wet-area installations, specify fully waterproof products and follow installation guidance.

How do I maintain and clean PVC vinyl floors?

Routine maintenance includes sweeping or vacuuming, and damp-mopping with a pH-neutral cleaner. Avoid harsh chemicals and abrasive pads. For commercial sites, implement a maintenance schedule including protective mats at entries to reduce grit and wear.

Do you offer samples and color matching?

Yes. 3c-floor provides physical sample swatches, digital color boards and printed mock-ups for project approval. For large projects we can provide pre-production samples and color proofs to ensure consistency across batches.

Request Samples, Technical Documents, or a Quote

To evaluate performance or request tender documents, use our online portal to Request A Quote. Our team will provide datasheets, test reports, and price breaks for volume orders.