Product Introduction

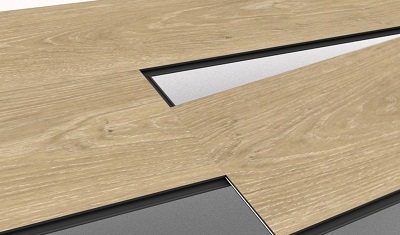

Stone Plastic Composite (SPC) flooring is a next-generation luxury vinyl product featuring a mineral (stone) and plastic composite core that provides outstanding rigidity and stability. Compared with traditional vinyl plank, SPC flooring resists warping and expansion, is 100% waterproof, and supports heavy traffic — making it suitable for kitchens, bathrooms, basements, retail stores and multi-family housing.

3C-FLOOR’s SPC collections are engineered with multi-layer construction: a durable wear layer, high-definition printed decor layer, SPC rigid core, and an optional attached acoustical pad for sound reduction and underfoot comfort. We offer both click-lock (floating) systems and glue-down options to fit different installation preferences.

Product Features

- Waterproof & Moisture Resistant: 100% waterproof SPC core — ideal for wet areas and below-grade installations.

- Rigid Stone-Plastic Core: Superior dimensional stability; low thermal expansion compared with WPC or LVP.

- High Durability Wear Layer: Transparent wear layer (0.3mm – 0.7mm options) resists scratches, stains and commercial foot traffic.

- Realistic Textures: Embossed, registered grain and low-gloss finishes that mimic natural hardwood and stone.

- Easy Installation: Click-lock (Unilin/Valinge style) floating installation or glue-down; suitable for DIY or professional installers.

- Acoustic & Comfort Options: Attached EVA or IXPE underlayment for sound reduction and thermal comfort.

- Low Maintenance: Simple cleaning — sweeping and damp mopping; no sanding or refinishing needed.

Product Specifications (Typical Ranges)

| Specification | Typical Value / Options |

|---|---|

| Construction | Wear Layer / Printed Decor / SPC Core / IXPE or EVA Pad (optional) |

| Wear Layer Thickness | 0.3 mm (residential) / 0.5 mm (commercial) / up to 0.7 mm (heavy traffic) |

| Overall Thickness | 4.0 mm — 8.0 mm (including pad) |

| Plank Size | 1220×180 mm, 1220×225 mm, 180×1200 mm, 150×900 mm (custom lengths/widths available) |

| Core Density | >1200 kg/m³ (mineral-plastic composite) |

| Edge Profile | 0.3mm V-groove / Micro bevel / Square edge |

| Locking System | Click-lock Unilin / Valinge / Drop-lock options |

| AC Rating | AC3 / AC4 / AC5 (select wear layer options) |

| Fire Rating | Class Bfl-s1 / EN13501 (select ranges) |

| Warranty | Residential: 15–25 years; Commercial: 5–10 years (subject to SKU) |

Note: Values above are typical product ranges. Exact specifications, test reports and SKU-level data are provided on request.

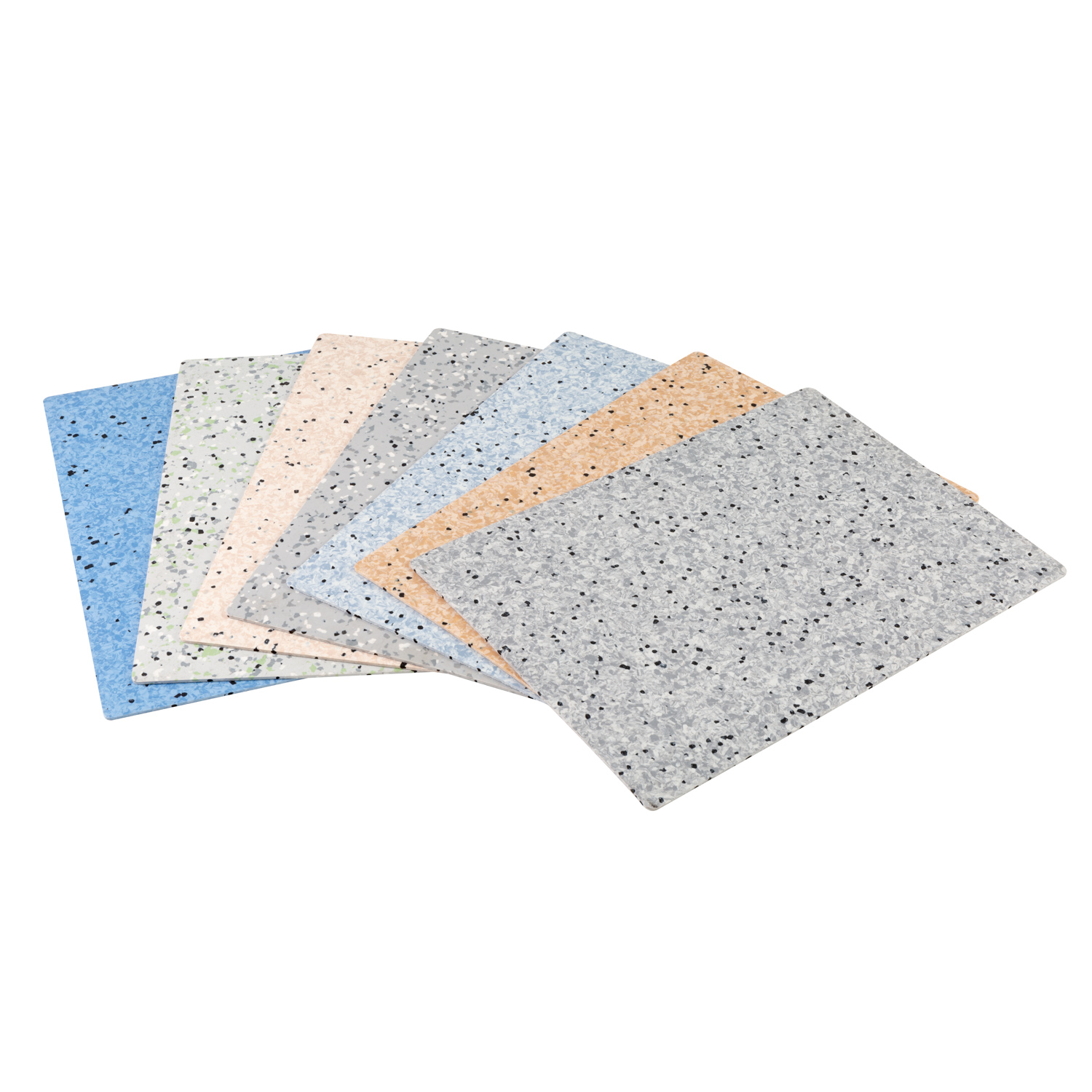

Product Colors & Finishes

Our SPC collections include a broad palette of wood and stone visuals:

- Authentic oak, walnut, maple, hickory and ash wood visuals — natural, grey, and whitewashed tones

- Stone and ceramic looks — travertine, limestone and slate patterns

- Matte, low-sheen and hand-scraped textures

- Specialty finishes: UV lacquer, oil-look surface and anti-slip textures for wet areas

Product Application

Stone Plastic Composite flooring is versatile — common applications include:

- Residential: Living rooms, kitchens, bathrooms (with waterproof installation), basements

- Commercial: Retail shops, offices, showrooms, medical clinics (selected wear layer)

- Hospitality: Hotel rooms, lobbies and conference spaces

- Multi-Family: Apartments and condominiums with high foot traffic

- Renovation Projects: Over existing subfloors (vinyl, ceramic, concrete) with proper prep

3C-FLOOR Company Profile

3C-FLOOR is a specialist in engineered resilient flooring, providing high-performance SPC solutions for global contractors, architects, and distributors. Our product development focuses on material science, realistic décor reproduction and installation efficiency. Headquartered at www.3c-floor.com, we combine in-house R&D, automated production lines and rigorous QC to deliver consistent product quality.

We collaborate with project teams to specify the right SPC grade, wear layer, and acoustic options for each project — ensuring long-term performance and occupant comfort.

Certificates & Standards

3C-FLOOR SPC products meet international standards and testing regimes. Available certificates include:

- ISO 9001 Quality Management System

- EN 13813 / EN 13501 (selected fire performance reports)

- ASTM test reports (where required) for wear and slip resistance

- VOC emissions testing: TVOC / E1 / FloorScore® / equivalent depending on region

- CE marking and product declarations for EU markets

Detailed test reports and certificate copies are available upon request for specification and tender documentation.

Why Choose 3C-FLOOR SPC?

- Proven performance: Rigid SPC cores reduce telegraphing and keep planks flat under variable humidity and temperature.

- Comprehensive selection: Multiple wear layers, textures and acoustic options for residential and commercial use.

- Quality control: Automated production lines with strict incoming raw material inspection.

- Technical support: Specification assistance, installation guides and on-site training for installers.

- Global logistics: Export experience to Europe, North America, Asia and Middle East — competitive lead times and packaging.

Installation Precautions

- Acclimate planks in unopened packs at jobsite temperature for 48 hours before installation.

- Subfloor must be clean, dry, level (≤3mm per 1m), and free of adhesives or debris.

- Use recommended underlayment where required — attached IXPE pads reduce noise; additional acoustic membranes may be needed for commercial specs.

- Follow manufacturer’s click-lock assembly instructions; maintain minimum expansion gaps around perimeter (typically 4–8 mm).

- For glue-down installations, use approved adhesives and follow open/working time guidelines.

- After installation, avoid heavy rolling loads for 24–48 hours and protect floor during remaining construction.

Sold to Countries & Distribution

3C-FLOOR SPC is exported worldwide. Key markets include the United States, Canada, United Kingdom, Germany, France, Australia, New Zealand, UAE and Southeast Asia. We work with distributors, flooring wholesalers and project contractors — contact us to find your local reseller or to arrange FOB/CIF/DDP shipping.

FAQs — Stone Plastic Composite Flooring

Q: Is SPC flooring better than traditional vinyl plank?

A: SPC’s rigid mineral core offers superior dimensional stability and reduced thermal expansion compared with flexible LVP. It’s typically more durable under heavy loads and better suited for wide-plank formats.

Q: Can SPC be installed in bathrooms and wet areas?

A: Yes — SPC is 100% waterproof, but proper installation around fixtures and transitions is required to ensure a watertight result. Use recommended trims and sealants where appropriate.

Q: How do I maintain SPC flooring?

A: Regular sweeping and a damp mop with a pH-neutral cleaner is sufficient. Avoid abrasive scrubbing or wax-based cleaners. Use felt pads under furniture.

Q: Will SPC floor feel cold or hard underfoot?

A: SPC has a rigid feel compared to wood; adding an attached pad (IXPE/EVA) improves thermal comfort and underfoot softness. Underfloor heating compatibility varies by product — consult our technical sheet.

Q: Do you provide commercial warranties?

A: Yes. Warranty terms vary by SKU and application (residential vs commercial). Standard residential warranties range 15–25 years; commercial warranties from 5–10 years. See product datasheets for specifics.