Top 10 SPC Flooring Manufacturers in China — Buyer’s Guide & 3C-Floor Company Overview

Updated guide for buyers looking to source high-quality SPC flooring from China. This comprehensive resource explains product specifications, performance benefits, manufacturing capacity, certifications, installation tips and export markets — with a special focus on flooring solutions offered by 3C-Floor.

Need a fast quote? Request A Quote

What is SPC flooring? (Short primer)

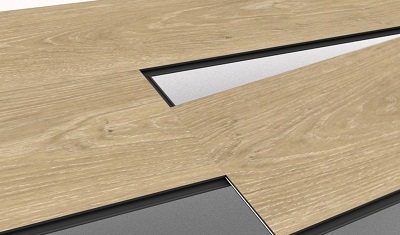

SPC stands for Stone Plastic Composite or Stone Polymer Composite. It’s a rigid core luxury vinyl product engineered from a mixture of limestone powder and stabilizers bound together with high-grade PVC. SPC delivers exceptional dimensional stability, superior waterproof performance, strong impact resistance, and easier installation — making it a preferred choice across residential, commercial and institutional projects. Explore our SPC product range here: SPC flooring.

Why buyers choose SPC over traditional vinyl or laminate

Top 10 SPC Flooring Manufacturers in China — what to look for

When evaluating China-based SPC suppliers, prioritize:

- Production capacity and lead time

- Available wear layer options (0.3mm → 0.7mm+)

- Dimensions and formats (thickness, plank size, bevels)

- Certifications (CE, ISO9001, FloorScore, EPD, ASTM where applicable)

- Technical lab testing (ABRASION, EN660, RUT, etc.)

- After-sales support and installation training

Typical SPC product specification (example model)

| Item | Specification / Typical Values |

|---|---|

| Core composition | Stone plastic composite (Limestone powder + PVC + stabilizers) |

| Total thickness | 4.0mm / 4.2mm / 5.0mm / 6.0mm (typical) |

| Wear layer | 0.3mm, 0.5mm, 0.7mm, 1.0mm options |

| Surface | UV coated, Embossed / Registered Embossed |

| Dimensions | 1220 x 180mm, 1220 x 226mm, 180 x 180mm (tiles) — custom sizes available |

| Edge | Micro-beveled / Square edge |

| Installation | Floating click-lock system / glue down (optional) |

| Underlayment | Integrated IXPE/ cork / separate acoustic underlay |

| Fire rating | Bfl-s1 / Class B (dependent on formula and testing) |

| Packing | 12 planks/box — boxes per pallet vary by profile |

Product Introduction — 3C-Floor SPC series

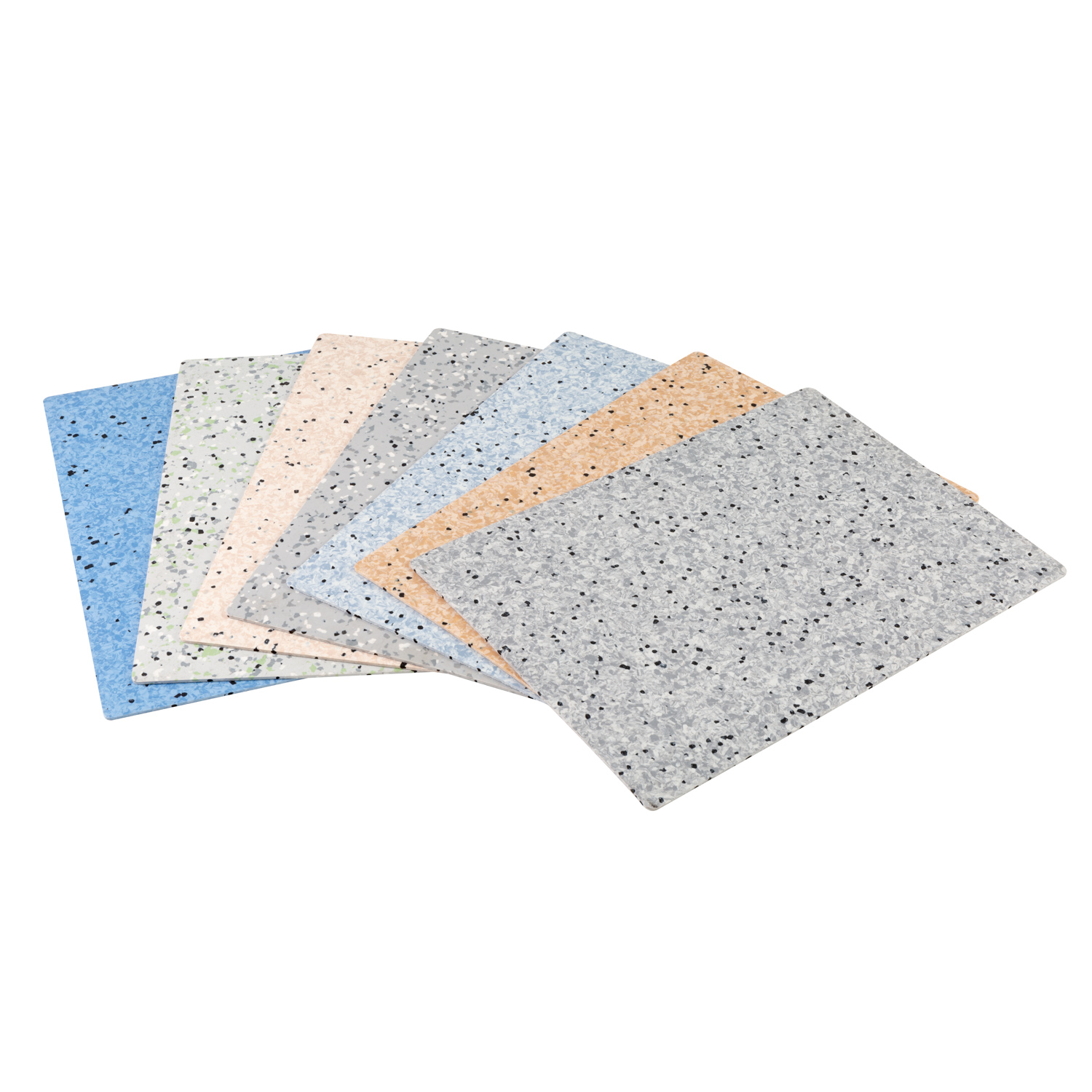

3C-Floor designs and manufactures high-performance SPC products engineered for global markets. Our SPC collection blends realistic wood-grain visuals with robust wear layers and a rigid, dimensionally stable core. Each plank is finished with a UV-cured urethane layer for scratch and stain resistance. Learn more about our complete flooring catalog and technical sheets on the official site.

Product Features (detailed)

Waterproof & Moisture Resistant

Inorganic core construction means SPC resists water and humidity — ideal for bathrooms, kitchens, basements and high-traffic commercial spaces.

Superior Dimensional Stability

SPC boards maintain flatness and resist warping; suitable for underfloor heating systems depending on specification.

High Wear Resistance

Choose thicker wear layers (0.55–1.0mm) for heavy commercial traffic. 3C-Floor offers abrasion-resistant coatings and optional anti-slip surface treatments.

Acoustic Comfort

Integrated underlayer options and optional cork-backed products improve acoustic performance and foot comfort.

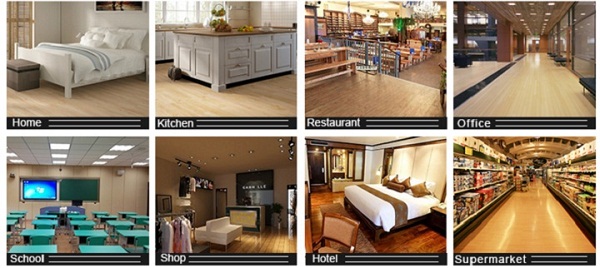

Applications — where SPC performs best

SPC is a versatile solution widely used in:

- Residential homes — living rooms, kitchens, hallways

- Multi-family developments & apartments

- Retail stores, showrooms and shopping malls

- Offices and co-working spaces

- Hospitality — hotel rooms, corridors, lobbies

- Healthcare non-critical zones (corridors, lounges)

- Light industrial & exhibition halls (with heavy-duty wear layers)

3C-Floor Company Profile

3C-Floor is a leading manufacturer and exporter of rigid-core SPC and LVT products based in China. We integrate R&D, production and quality control to deliver customized SPC flooring solutions for distributors, retailers and project contractors worldwide. Our factory uses advanced extrusion lines, precision printing and UV curing lines to maintain consistent quality across large-volume orders.

Factory capacity & services

Typical annual output: multi-million square meters (varies by SKU). Capabilities include private label, OEM packaging, custom plank sizes, and lane-specific wear layer formulas. 3C-Floor provides pre-shipment inspection, third-party testing and consolidated shipping support.

Certificates & Testing

3C-Floor maintains multiple quality and environmental certificates to meet export market requirements such as:

- ISO 9001 Quality Management System

- CE marking where applicable

- FloorScore / Indoor Air Quality testing (selected collections)

- Third-party abrasion & slip resistance test reports (EN/ASTM standards)

- Environmental Product Declarations (EPD) on demand

Contact our sales team for copies of certificates and independent lab reports for specific batches.

Why Choose 3C-Floor?

- Technical expertise: Decades of experience in vinyl and rigid core manufacturing.

- Custom solutions: Product and packing customization for retail and project needs.

- Quality assurance: Inline QC and third-party lab testing to ensure consistent board performance.

- Competitive lead times: Optimized production scheduling and export logistics.

- After-sales support: Installation guidance, replacement policy and training for installers.

Installation Precautions & Best Practices

Proper installation maximizes the lifetime and appearance of SPC floors. Key precautions:

- Acclimatize planks on-site for 24–48 hours in packaging before installation.

- Ensure the subfloor is clean, dry and level (max deviation typically 3 mm per 2 m).

- Use recommended underlayment for acoustic comfort and thermal insulation.

- Maintain expansion joints at walls and fixed objects as per product guidelines (typically 6–10 mm).

- Avoid direct prolonged exposure to extreme heat sources (e.g., industrial ovens).

- Follow manufacturer instructions for areas with underfloor heating (maximum surface temperature limits).

Sold To / Export Markets

3C-Floor exports SPC and other flooring products to markets globally, including:

- North America (USA, Canada)

- Europe (UK, Germany, France, Netherlands, Scandinavia)

- Australia & New Zealand

- Middle East & GCC

- Africa (selected distributors)

- Latin America (Brazil, Chile, Mexico)

Top 10 SPC Manufacturers — buyer checklist

This guide covers criteria to vet manufacturers. When you request samples or quotations from suppliers, ask for:

- Physical sample with the specified wear layer and finish.

- Detailed technical data sheet and safety data sheet (SDS).

- Batch-level test certificates (abrasion, slip resistance, formaldehyde / VOC).

- MOQ, lead time, and price per sqm CIF / FOB.

- Customization options for print, bevel, and packaging.

FAQs (structured & helpful)

Frequently Asked Questions

Q: What is the difference between SPC and WPC?

A: SPC (Stone Plastic Composite) uses a mineral (limestone) core for rigidity; WPC (Wood Plastic Composite) uses wood fibers and has a softer core. SPC is generally more dimensionally stable and better for high-traffic and wet areas.

Q: Is SPC flooring waterproof?

A: Yes — the rigid mineral core makes SPC highly waterproof. Joints must be properly installed and accessories (trim, thresholds) must be used to maintain water resistance at transitions.

Q: Can SPC be installed over underfloor heating?

A: Many SPC products are compatible with low-temperature underfloor heating systems. Check product-specific maximum surface temperature and follow installation guidelines.

Q: How do I clean and maintain SPC floors?

A: Regular sweeping and damp mopping with mild cleaners is sufficient. Avoid abrasive scrubbers and harsh solvents. Use felt pads under furniture to prevent scratches.

Q: Where can I request samples or a quote?

A: Use our quick form — Request A Quote — to get samples, pricing and lead time information.

Relevant keywords (SEO & long-tail)

SPC flooring, SPC floor manufacturers China, rigid core SPC panels, waterproof SPC vinyl, SPC flooring suppliers for export, commercial SPC flooring, click lock SPC flooring, SPC flooring installation guide, best SPC flooring China, 3C-Floor SPC.

How to request a sample & get started

1) Prepare your project details: area (sqm), preferred plank size, wear layer, and desired finish.

2) Send the details through Request A Quote or email our sales team. We provide free standard samples (courier charges may apply) and project-specific technical drawings for larger orders.

Commercial terms & logistics

Standard terms: FOB Shanghai / CIF destination (negotiable). Lead time typically ranges from 20–45 days depending on order size and SKU customization. Full container and LCL shipments available. 3C-Floor can arrange consolidated shipping and handle export documentation.

Contact & Next Steps

Ready to compare offers from the top SPC manufacturers and order test samples? Start by requesting a quote: