What is vinyl flooring? Quick primer

Vinyl flooring is a family of resilient floor coverings manufactured primarily from PVC (polyvinyl chloride) together with stabilizers, plasticizers (or rigid cores), fillers and decorative layers. Styles include Luxury Vinyl Tile (LVT), Luxury Vinyl Plank (LVP), Sheet Vinyl, and rigid-core variants such as WPC and SPC. Vinyl combines realistic visuals (wood, stone) with water resistance, wear-layer protection, and a range of thicknesses to suit residential and commercial projects.

Types of vinyl products commonly produced by Chinese manufacturers

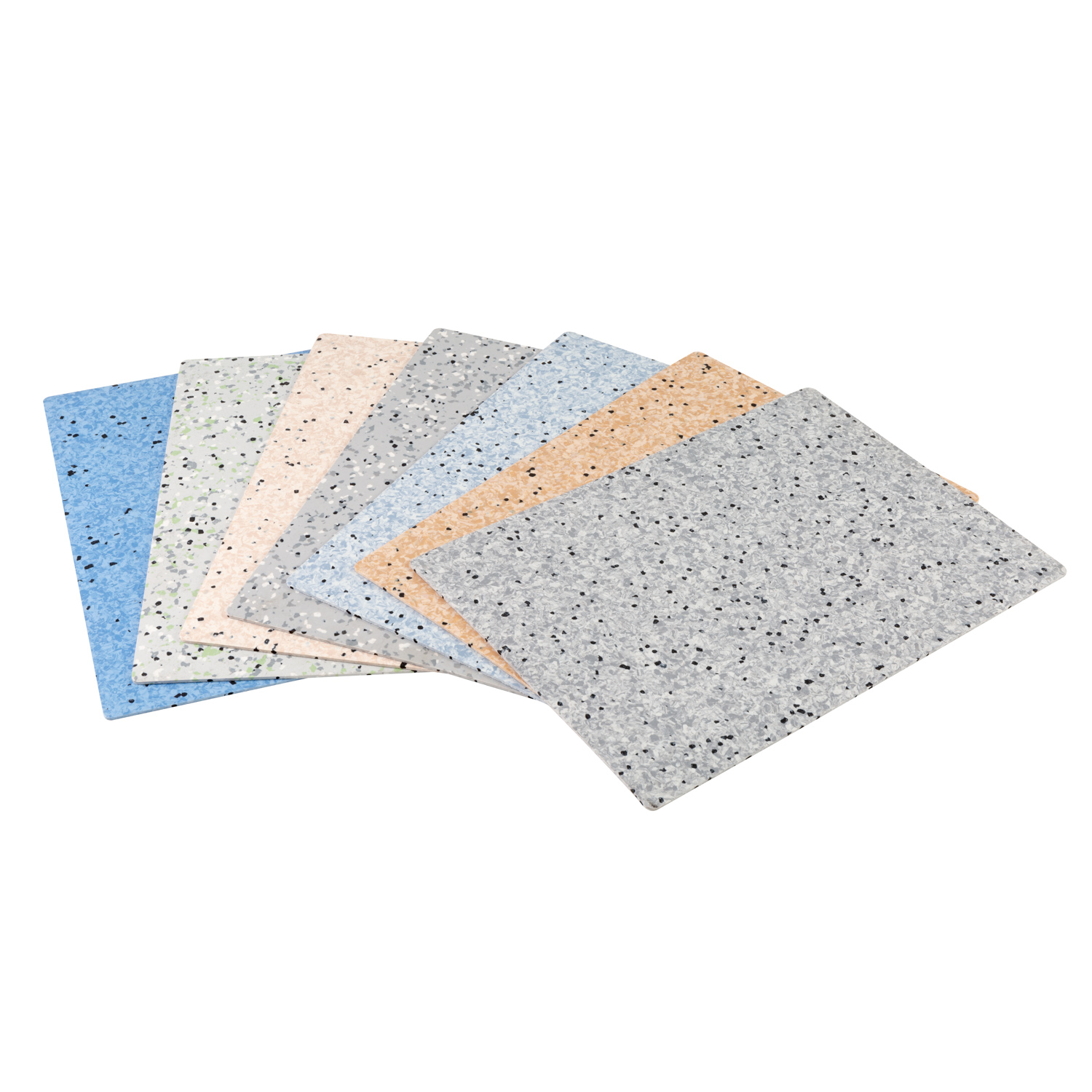

- Sheet Vinyl — continuous, flexible sheet for seamless installations and wet-area applications.

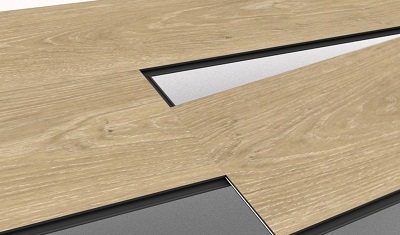

- LVT / LVP (Luxury Vinyl Tile / Plank) — printed decorative layer + clear wear layer; available in click or glue-down formats.

- Rigid Core (WPC) — wood-plastic composite core offering better comfort and insulation.

- Rigid Core (SPC) — stone plastic composite core for exceptional dimensional stability and waterproof performance. SPC flooring is covered in our dedicated technical pages.

- Glue-down luxury vinyl — thinner profiles for areas requiring low build-up.

Why source vinyl flooring from China?

China hosts a mature vinyl manufacturing ecosystem: integrated chemical suppliers, large-scale extrusion/lamination lines, experienced printing and UV coating processes, and reliable logistics for global export. Competitive pricing, flexible OEM capabilities, and rapid customization make China a common sourcing destination for distributors and project buyers worldwide.

3C-Floor Product Introduction — our vinyl range

3C-Floor manufactures a full vinyl portfolio including LVT/LVP, sheet vinyl, acoustic vinyl with IXPE backing, and rigid-core products. Our vinyl lines come with multiple wear layer options (0.2mm → 1.0mm), commercial-grade UV-cured coatings, and registered embossing to enhance realism and slip resistance. Samples and technical datasheets are available on request.

Signature product families (examples)

- Residential LVP series — 4.0mm total thickness with 0.3mm wear layer, click-lock system, realistic wood visuals.

- Commercial LVT heavy-duty — 5.0mm total thickness with 0.7–1.0mm wear layer and enhanced PVC backing for static load resistance.

- Acoustic vinyl — integrated IXPE underlayer for improved sound absorption and foot comfort.

- Sheet vinyl homogeneous / heterogeneous — roll goods in 2m / 3m widths for continuous installations in healthcare and education.

- Rigid core SPC / WPC — click-lock cores engineered for wet areas and high-traffic commercial zones. Learn more about our rigid core range here: SPC flooring.

Product Specifications (typical ranges)

| Parameter | Typical value / options |

|---|---|

| Total thickness | 2.0mm, 2.5mm, 3.0mm, 4.0mm, 5.0mm |

| Wear layer | 0.2mm (residential) — 1.0mm (heavy commercial) |

| Plank size | 1220×180 mm, 1520×180 mm, 180×180 mm tiles — custom sizes available |

| Surface treatment | PU, UV-cured urethane, enhanced scratch coating, registered embossing |

| Core types | Flexible PVC core, WPC core, SPC core |

| Installation | Click-lock floating, glue-down, loose lay |

| Acoustic underlay | Integrated IXPE, separate cork or felt underlayment options |

| Packing | Boxes per pallet vary by SKU; protective film and carton labelling |

Key product features & benefits

Applications — where vinyl excels

Vinyl is used across many sectors due to its flexibility and performance:

- Residential: living rooms, kitchens, bedrooms, basements

- Multifamily & student housing: cost-effective, low-maintenance solutions

- Retail and showrooms: durable surfaces with design flexibility

- Healthcare: sheet vinyl options for infection control and seam welding

- Education & public buildings: slip-resistant, easy to clean surfaces

- Hospitality: hotel rooms, corridors and ballrooms (commercial wear layers)

3C-Floor — Company Profile

3C-Floor is a professional manufacturer and exporter of vinyl floor coverings based in China. We combine R&D, material science, and large-scale manufacturing to produce competitively priced LVT/LVP, sheet vinyl, and rigid core systems for global clients. With modern production lines and stringent quality control, we support OEM and private label programs for distributors, contractors and retail chains.

Capabilities & services

Our facility is equipped for digital printing, UV coating, embossing, and lamination. We offer:

- Custom décor and print development

- Multiple wear-layer formulations and surface finishes

- Technical sample support and lab testing

- Packing customization and retail-ready displays

- Project support, including layout recommendations and installation training

Certificates & compliance

Quality and regulatory compliance are essential for export. 3C-Floor routinely secures:

- ISO 9001 Quality Management System certification

- CE marking and test reports for applicable EU standards

- FloorScore or Indoor Air Quality testing for low VOC emissions on select collections

- EN and ASTM abrasion & slip resistance reports upon request

For project bids we can deliver batch-level test reports and third-party lab certifications.

Why choose 3C-Floor as your vinyl supplier?

- Consistent quality: in-line QC and final inspection to reduce defective rates.

- Flexible MOQ: support for sample orders up to full container loads.

- Technical support: specification advice, installation guides and on-demand testing.

- Competitive logistics: FOB/CIF options, consolidated shipments and export documentation support.

- Customization: private label packaging, custom print repeats and bespoke beveling.

Installation precautions & best practices

Proper installation ensures durability and appearance. Key recommendations:

- Acclimatize materials for 24–48 hours in original packaging at the site temperature.

- Ensure subfloor is clean, dry and level (typical tolerance: ≤ 3 mm over 2 m).

- Follow manufacturer guidelines for adhesives if glue-down method is used.

- Maintain expansion gaps around perimeter and fixed objects to allow movement.

- For sheet vinyl and healthcare applications, use professional welding for seams to maintain hygiene and waterproofing.

- Protect newly installed surfaces from heavy loads and traffic for recommended curing times.

Export markets — where we ship

3C-Floor exports vinyl products globally. Common destinations include:

- North America (USA & Canada)

- European Union & UK

- Australia & New Zealand

- Middle East & GCC

- Latin America

- Africa (selected partners)

Commercial terms & lead times

Typical trade terms include FOB (Shanghai/Ningbo) and CIF. Lead time depends on SKU complexity and order volume — standard production lead times range from 20 to 45 days after pre-production sample approval. For most LVT orders we recommend confirming finish and wear-layer options before production to avoid delays.

FAQs — schema-enhanced answers

Frequently Asked Questions

Q: What is the difference between LVT and LVP?

A: The terms LVT (Luxury Vinyl Tile) and LVP (Luxury Vinyl Plank) describe formats — tiles vs planks — rather than composition. Both use printed decorative layers and protective wear layers; selection depends on design preference and installation method.

Q: Are vinyl floors waterproof?

A: Many vinyl products are highly water-resistant; rigid-core types and welded sheet installations provide excellent performance in wet areas. However, correct installation and seam treatment are essential to maintain water-tightness.

Q: Can vinyl be installed over radiant heating?

A: Some vinyl products are suitable for low-temperature radiant heating systems. Always consult product-specific maximum surface temperature limits and follow installation instructions.

Q: How long do vinyl floors typically last?

A: Lifespan depends on wear layer thickness, traffic and maintenance. Residential-grade vinyl with a 0.2–0.3mm wear layer may last 8–12 years; commercial-grade with 0.7–1.0mm wear layer can last significantly longer under heavy traffic.

Q: Where can I request samples or a quote?

A: Request samples and pricing via our online form: Request A Quote.

Relevant keywords & long-tail phrases

vinyl flooring manufacturers China, LVT suppliers China, waterproof vinyl plank supplier, luxury vinyl tile exporter, best vinyl flooring manufacturers, commercial vinyl flooring China, vinyl plank factory, acoustic vinyl flooring China, 3C-Floor vinyl collection, low-VOC vinyl flooring.

How to request samples and start a project

1) Prepare project details: total area (sqm), preferred product type (LVT/LVP/sheet/SPC), wear layer, plank size and packing preferences.

2) Submit details via Request A Quote or email our sales team. We will provide lead times, FOB/CIF pricing and sample arrangements.

Contact & next steps

Ready to compare offers from trusted Chinese vinyl flooring manufacturers? Start by requesting samples and technical datasheets. For tailored project support and OEM options, contact 3C-Floor through our request form.